详细描述

约翰迪尔压路机应用的发动机零件

设备型号

备注

646

To ESN 335,845, Block (m): R43310, R45980, R47020, R47110

646B

To ESN 335,845, Block (m): R43310, R45980, R47020, R47110

646C

Con Rod (m) R57303, R67320

646B

Con Rod (m) R48315, R53287, R58883, R66926

迪尔 6081 高压缩活塞

| 设备型号 | 备注 |

|---|---|

| 646 | To ESN 335,845, Block (m): R43310, R45980, R47020, R47110 |

| 646B | To ESN 335,845, Block (m): R43310, R45980, R47020, R47110 |

| 646C | Con Rod (m) R57303, R67320 |

| 646B | Con Rod (m) R48315, R53287, R58883, R66926 |

|

| |||||||||||||||||||||||||||

|

型号 |

数量 |

描述 |

|

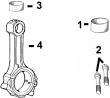

TR116081 |

6 |

约翰迪尔(John Deere) 强鹿6081发动机连杆瓦(标准 |

|

TR66452 |

12 |

约翰迪尔(John Deere) 强鹿6081发动机连杆螺钉 |

|

TR71918 |

1 |

约翰迪尔(John Deere) 强鹿6081发动机GASKET, OIL PAN |

|

TRE529319 |

6 |

约翰迪尔(John Deere) 强鹿6081发动机主轴瓦(标准) |

|

TRE529320 |

1 |

约翰迪尔(John Deere) 强鹿6081发动机止推瓦(标准) |

|

TRE506222 |

1 |

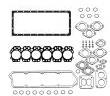

约翰迪尔(John Deere) 强鹿6081发动机GASKET, CYL HEAD SET |

|

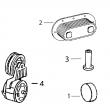

TRE508156 |

6 |

约翰迪尔(John Deere) 强鹿6081发动机活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈,低压缩 |

约翰迪尔(John Deere) 强鹿6081发动机内部修理套件TIK504202A

|

型号 |

数量 |

描述 |

|

TR116081 |

6 |

约翰迪尔(John Deere) 强鹿6081发动机连杆瓦(标准 |

|

TR501035 |

12 |

约翰迪尔(John Deere) 强鹿6081发动机连杆螺钉 |

|

TR71918 |

1 |

约翰迪尔(John Deere) 强鹿6081发动机GASKET, OIL PAN |

|

TRE529319 |

6 |

约翰迪尔(John Deere) 强鹿6081发动机主轴瓦(标准) |

|

TRE529320 |

1 |

约翰迪尔(John Deere) 强鹿6081发动机止推瓦(标准) |

|

TRE506222 |

1 |

约翰迪尔(John Deere) 强鹿6081发动机GASKET, CYL HEAD SET |

|

TRE508156 |

6 |

约翰迪尔(John Deere) 强鹿6081发动机活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈,低压缩 |

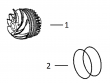

(1)用螺旋油泵驱动齿轮。 不要与HPCR燃油系统一起使用。

(2)带直油泵传动齿轮。

(3)纸垫片。

(4)金属/橡胶垫圈。

(5)套件中均包含前部密封件。

(6)检查应用程序是否正确使用。

强鹿JOHN DEERE柴油机配件、发动机配件、发电机组:

RE533608、AR50041、RE515409P550758、P550020、P550595、P558329、P550351、P551421、P551423、P556745、P551428、P551422、P551435、P551434、P550192、P550397、P551352、P181054、P77868、P777869、P550667、P550779、P551345、P608667、P607557、P611856、P611857ignition off 2. keep cylinder 4 eui wires disconnected from eui 3. keep eui wiring harness connector at rear of cylinder head disconnected 4. using a multimeter, measure resistance between both of cylinder 4 eui harness eyelets greater than 20,000 ohms: faulty ecu connection or faulty eui wiring harness connection or faulty ecu less than 20,000 ohms: faulty eui wiring harness ctm188 (20mar01) 04-160-234 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=422 trouble code diagnostics&tests 04 160 235 ctm188 (20mar01) 04-160-235 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=423 trouble code diagnostics&tests 04 160 236 dpsg,rg40854,231 –19–30jun99–1/1 level 6 ecu - dtc spn 655 fmi 5 cylinder #5 eui circuit open rg10390 –19–23nov99 important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. eui (electronic unit injector) ? the fuel in 10.5 l&12.5 l engines is delivered by 6 (one for each cylinder) electronic unit injectors (euis). the euis are mounted in they cylinder head, under the valve cover, so that they spray directly into the center of the cylinder bore. each eui is an injection pump&injector combined, operating at much higher pressures than standard in-line or rotary injection pumps. the ecu controls the start of injection&the amount of fuel injected by turning the solenoid in the eui valve housing on&off which in turn opens&closes the eui spill valve. ? power is supplied to the euis for cylinders 1, 2, and 3 by a common wire,&to the euis for cylinders 4, 5,&6 by a different common wire. the ecu energizes&deenergizes the solenoids of individual euis by closing&opening the individual eui ground circuits. dtc spn 655 fmi 5 will set if: ? the ecu detects an open in the cylinder #5 eui circuit. if dtc spn 655 fmi 5 sets, the following will occur: ? cylinder #5 eui will not fire. ctm188 (20mar01) 04-160-236 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=424 trouble code diagnostics&tests ouo1004,0000cbc –19–08jan01–1/1 level 6 ecu - dtc spn 655 fmi 5 cylinder #5 eui circuit open - continued 04 160 237 – – –1/1 level 6 ecu - dtc spn 655 fmi 5 cylinder #5 eui circuit open diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of the 48-way ecu connector and the eui harness connector (located at the back of the cylinder head) looking for dirty, damaged,/poorly positioned terminals. – – –1/1 1 intermittent fault test important: if dtcs spn 611 fmi 3, spn 611 fmi 4,/spn 627 fmi 1 are active, repair those dtcs first. note: for wiring&theory of operation information, see dtc spn 655 fmi 5 cylinder #5 eui circuit open supporting information. 1. ignition on, engine off 2. using the dst, monitor dtcs on the active code display parameter 3. make note of any dtcs, then clear all dtcs 4. ignition on, engine running 5. using the dst, monitor dtcs on the active code display parameter spn 655 fmi 5 reoccurs: go to 2 spn 655 fmi 5 doesn’t reoccur: problem is intermittent. if no other codes are present, see intermittent fault diagnostics, earlier in this group. ctm188 (20mar01) 04-160-237 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=425 trouble code diagnostics&tests 04 160 238 – – –1/1 2 open wire in 90v supply/eui control wire test note: for wiring&theory of operation information, see dtc spn 655 fmi 5 cylinder #5 eui circuit open supporting information. 1. ignition off caution: possible strong electric shock hazard if engine is cranking or running 2. disconnect eui wiring harness connector at rear of cylinder head 3. disconnect 18-terminal half of 48-way ecu connector 4. using a multimeter, measure resistance between: ? terminal b in the harness end of the eui wiring harness connector&terminal b2 in the harness end of the ecu connector ? terminal f in the harness end of the eui wiring harness connector&terminal d2 in the harness end of the ecu connector both measurements 5.0 ohms/less: go to 3 measurement between b to b2 greater than 5 ohms: open in wire between terminal b&b2 measurement between f to d2 greater than 5 ohms: open in wire between terminal f&d2 – – –1/1 3 cylinder 5 eui test note: for wiring&theory of operation information, see dtc spn 655 fmi 5 cylinder #5 eui circuit open supporting information. 1. remove rocker arm cover 2. disconnect electrical connections to cylinder 5 eui&a known good eui 3. using a multimeter measure resistance between: ? the two terminals on cylinder 5 eui ? the two terminals on the know good eui 4. compare the measurements between the two euis note: because eui resistance varies with temperature, a comparison is used to compensate for the effects of temperature. typically, 安阳约翰迪尔柱塞2455-512批发,重庆约翰迪尔6068柴油机节温器多少钱,日照强鹿-约翰迪尔发动3029df128配件的价格,呼和浩特约翰迪尔机油滤清器RE504836价格行情,海西约翰迪尔传感器RE519144厂家供应,七台河约翰迪尔强鹿气门室盖垫片R524468多少钱,西宁强鹿4045柴油机气门弹簧公司,黔南约翰迪尔活塞RE30250公司,博尔塔拉美国强鹿JOHNDEERE柴油发电机配件价格,萍乡强鹿R123461风扇皮带哪里买,张家口JohnDeere气门油封RE519115多少钱,朔州约翰迪尔RE44574后油封的价格,岳阳强鹿STANADYNE燃油泵RE-518166批发,河南JohnDeereRE31973摇臂供应商,天津强鹿活塞RE507758批发,济南约翰迪尔发动机节温器代理商,鹰潭强鹿柴油发动机配件哪家买,南京强鹿6090柴油机活塞销供货商,鸡西johndeere约翰迪尔强鹿柴油机水泵诚信推荐,烟台强鹿柴油发动机大修包RE526727一级代理,开封JohnDeere柴油发动机大修包TRE532715价格行情,玉林强鹿凸轮轴衬套RE521756价格行情,澳门半岛强鹿柴油机R28811曲轴齿轮批发商,德宏强鹿凸轮轴塞R82007公司,阿勒泰强鹿滤芯滤清器RE57394价格行情,郑州强鹿6081柴油机进气门导管厂家供货,和田强鹿柴油机起动机RE70960一级代理,西宁强鹿气门座圈R501640厂家价格,抚顺强鹿柴油发电机喷油器RE48786厂家供货,九江强鹿滤芯滤清器RE58367信息,丽水强鹿6081发动机缸套水封圈哪里买,河池强鹿柴油机3029后油封厂家批发,吕梁约翰迪尔后油封RE44574一级代理,陇南JohnDeere喷油器O型圈RE528349批发价,酒泉约翰迪尔加大连杆瓦RE65909供货商,保山约翰迪尔拖拉机发动机柱塞诚信推荐,咸阳re504836机油滤清器约翰迪尔(强鹿)诚信推荐,淮安约翰迪尔气门锁夹R502371厂家供应,哈密约翰迪尔发动机气门导管诚信推荐,长治约翰迪尔R122191一级代理,榆林强鹿RE501578修理包厂家批发,舟山强鹿6090柴油发动机气门弹簧诚信推荐,克拉玛依约翰迪尔拖拉机发动机气缸垫哪家买,eui resistance should be 1.0-1.8 ohms. difference between measurements 0.2 ohms/less: go to 4 difference between measurements greater than 0.2 ohms: faulty cylinder 5 eui ctm188 (20mar01) 04-160-238 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=426 trouble code diagnostics&tests 04 160 239 – – –1/1 4 eui harness in cylinder head test note: for wiring&theory of operation information, see dtc spn 655 fmi 5 cylinder #5 eui circuit open supporting information. 1. ignition off 2. cylinder 5 eui wires disconnected from eui 3. disconnect eui wiring harness connector from rear of cylinder head 4. using a multimeter, measure resistance between: ? one of the cylinder 5 eui harness eyelet&the corresponding terminal at the connector on the rear of the cylinder head (either f/b, the eui’s are not polarity sensitive) ? the other cylinder 5 eui harness eyelet&the other corresponding terminal at the connector on the rear of the cylinder head both measurements 2.0 ohms/less: faulty ecu connection or faulty eui wiring harness connection or faulty ecu either measurements greater than 2.0 ohms: faulty eui harness in head ctm188 (20mar01) 04-160-239 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=427 trouble code diagnostics&tests 04 160 240 dpsg,rg40854,232 –19–30jun99–1/1 level 6 ecu - dtc spn 655 fmi 6 cylinder #5 eui circuit shorted rg10390 –19–23nov99 important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. eui (electronic unit injector) ? the fuel in 10.5 l&12.5 l engines is delivered by 6 (one for each cylinder) electronic unit injectors (euis). the euis are mounted in they cylinder head, under the valve cover, so that they spray directly into the center of the cylinder bore. each eui is an injection pump&injector combined, operating at much higher pressures than standard in-line or rotary injection pumps. the ecu controls the start of injection&the amount of fuel injected by turning the solenoid in the eui valve housing on&off which in turn opens&closes the eui spill valve. ? power is supplied to the euis for cylinders 1, 2, and 3 by a common wire,&to the euis for cylinders 4, 5,&6 by a different common wire. the ecu energizes&deenergizes the solenoids of individual euis by closing&opening the individual eui ground circuits. dtc spn 655 fmi 6 will set if: ? the ecu detects an open in the cylinder #5 eui circuit. if dtc spn 655 fmi 6 sets, the following will occur: ? cylinder #5 eui will not fire. ctm188 (20mar01) 04-160-240 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=428 trouble code diagnostics&tests ouo1004,0000cbd –19–08jan01–1/1 level 6 ecu - dtc spn 655 fmi 6 cylinder #5 eui circuit shorted - continued 04 160 241 – – –1/1 level 6 ecu - dtc spn 655 fmi 6 cylinder #5 eui circuit shorted diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of the 48-way ecu connector and the eui harness connector (located at the rear of the cylinder head) looking for dirty, damaged,/poorly positioned terminals. – – –1/1 1 intermittent fault test important: if dtcs spn 611 fmi 3,, spn 611 , fmi 4,/spn 627 fmi 1 are active, repair those dtcs first. note: for wiring&theory of operation information, see dtc spn 655 fmi 6 cylinder #5 eui circuit shorted supporting information. 1. ignition on, engine off 2. using the dst, monitor dtcs on the active code display parameter 3. make note of any dtcs, then clear all dtcs 4. ignition on, engine running 5. using the dst, monitor dtcs on the active code display parameter spn 655 fmi 6 reoccurs: go to 2 spn 655 fmi 6 doesn’t reoccur: problem is intermittent. if no other codes are present, see intermittent fault diagnostics, earlier in this group. ctm188 (20mar01) 04-160-241 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=429 trouble code diagnostics&tests 04 160 242 – – –1/1 2 short in eui wiring harness test note: for wiring&theory of operation information, see dtc spn 655 fmi 6 cylinder #5 eui circuit shorted supporting information. 1. ignition off caution: possible strong electric shock hazard if engine is cranking or running 2. disconnect 18-terminal half of 48-way ecu connector 3. disconnect eui wiring harness connector at rear of cylinder head 4. using a multimeter, measure resistance between terminal b in the harness end of the eui wiring connector and: ? terminal c in the harness end of the eui wiring connector ? terminal f in the harness end of the eui wiring connector both measurements greater than 20,000 ohms: go to 3 either measurement less than 20,000 ohms: short in ecu wiring harness – – –1/1 3 cylinder 5 eui test note: for wiring&theory of operation information, see dtc spn 655 fmi 6 cylinder #5 eui circuit shorted supporting information. 1. remove rocker arm cover 2. disconnect electrical connections to cylinder 5 eui&a known good eui 3. using a multimeter measure resistance between: ? the two terminals on cylinder 5 eui ? the two terminals on the known good eui 4. compare the measurements between the two euis note: because eui resistance varies with temperature, a comparison is used to compensate for the effects of temperature. typical eui resistance should be 1.0-1.8 ohms. difference between measurements 0.2 ohms/less: go to 4 difference between measurements greater than 0.2 ohms: faulty cylinder 5 eui – – –1/1 4 eui wiring harness in cylinder head test note: for wiring&theory of operation information, see dtc spn 655 fmi 6 cylinder #5 eui circuit shorted supporting information. 1. ignition off 2. keep cylinder 5 eui wires disconnected from eui 3. keep eui wiring harness connector at rear of cylinder head disconnected 4. using a multimeter, measure resistance between both of cylinder 5 eui harness eyelets greater than 20,000 ohms: faulty ecu connection or faulty eui wiring harness connection or faulty ecu less than 20,000 ohms: faulty eui wiring harness ctm188 (20mar01) 04-160-242 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=430 trouble code diagnostics&tests 04 160 243 ctm188 (20mar01) 04-160-243 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=431 trouble code diagnostics&tests 04 160 244 dpsg,rg40854,233 –19–30jun99–1/1 level 6 ecu - dtc spn 656 fmi 5 cylinder #6 eui circuit open rg10391 –19–23nov99 important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. eui (electronic unit injector) ? the fuel in 10.5 l&12.5 l engines is delivered by 6 (one for each cylinder) electronic unit injectors (euis). the euis are mounted in they cylinder head, under the valve cover, so that they spray directly into the center of the cylinder bore. each eui is an injection pump&injector combined, operating at much higher pressures than standard in-line or rotary injection pumps. the ecu controls the start of injection&the amount of fuel injected by turning the solenoid in the eui valve housing on&off which in turn opens&closes the eui spill valve. ? power is supplied to the euis for cylinders 1, 2, and 3 by a common wire,&to the euis for cylinders 4, 5,&6 by a different common wire. the ecu energizes&deenergizes the solenoids of individual euis by closing&opening the individual eui ground circuits. dtc spn 656 fmi 5 will set if: ? the ecu detects an open in the cylinder #6 eui circuit. if dtc spn 656 fmi 5 sets, the following will occur: ? cylinder #6 eui will not fire. ctm188 (20mar01) 04-160-244 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=432 trouble code diagnostics&tests ouo1004,0000cbe –19–08jan01–1/1 level 6 ecu - dtc spn 656 fmi 5 cylinder #6 eui circuit open - continued 04 160 245 – – –1/1 level 6 ecu - dtc spn 656 fmi 5 cylinder #6 eui circuit open diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of the 48-way ecu connector and the eui harness connector (located at the back of the cylinder head) looking for dirty, damaged,/poorly positioned terminals. – – –1/1 1 intermittent fault test important: if dtcs spn 611 fmi 3, spn 611 fmi 4,/spn 627 fmi 1 are active, repair those dtcs first note: for wiring&theory of operation information, see dtc spn 656 fmi 5 cylinder #6 eui circuit open supporting information. 1. ignition on, engine off 2. using the dst, monitor dtcs on the active code display parameter 3. make note of any dtcs, then clear all dtcs 4. ignition on, engine running 5. using the dst, monitor dtcs on the active code display parameter spn 656 fmi 5 reoccurs: go to 2 spn 656 fmi 5 doesn’t reoccur: problem is intermittent. if no other codes are present, see intermittent fault diagnostics, earlier in this group. ctm188 (20mar01) 04-160-245 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=433 trouble code diagnostics&tests 04 160 246 – – –1/1 2 open wire in 90v supply/eui control wire test note: for wiring&theory of operation information, see dtc spn 656 fmi 5 cylinder #6 eui circuit open supporting information. 1. ignition off caution: possible strong electric shock hazard if engine is cranking or running 2. disconnect eui wiring harness connector at rear of cylinder head 3. disconnect 18-terminal half of 48-way ecu connector 4. using a multimeter, measure resistance between: ? terminal e in the harness end of the eui wiring harness connector&terminal b1 in the harness end of the ecu connector ? terminal f in the harness end of the eui wiring harness connector&terminal d2 in the harness end of the ecu connector both measurements 5 ohms/less: go to 3 measurement between e to b1 greater than 5 ohms: open in wire between terminal e&b1 measurement between f to d2 greater than 5 ohms: open in wire between terminal f&d2 – – –1/1 3 cylinder 6 eui test note: for wiring&theory of operation information, see dtc spn 656 fmi 5 cylinder #6 eui circuit open supporting information. 1. remove rocker arm cover 2. disconnect electrical connections to cylinder 6 eui&a known good eui 3. using a multimeter measure resistance between: ? the two terminals on cylinder 6 eui ? the two terminals on the know good eui 4. compare the measurements between the two euis note: because eui resistance varies with temperature, a comparison is used to compensate for the effects of temperature. typically eui resistance should be 1.0-1.8 ohms. difference between measurements 0.2 ohms/less: go to 4 difference between measurements greater than 0.2 ohms: faulty cylinder 6 eui ctm188 (20mar01) 04-160-246 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=434 trouble code diagnostics&tests 04 160 247 – – –1/1 4 eui harness in cylinder head test note: for wiring&theory of operation information, see dtc spn 656 fmi 5 cylinder #6 eui circuit open supporting information. 1. ignition off 2. cylinder 6 eui wires disconnected from eui 3. disconnect eui wiring harness connector from rear of cylinder head 4. using a multimeter, measure resistance between: ? one of the cylinder 6 eui harness eyelet&the corresponding terminal at the connector on the rear of the cylinder head (either f/e, the eui’s are not polarity sensitive) ? the other cylinder 6 eui harness eyelet&the other corresponding terminal at the connector on the rear of the cylinder head both measurements 2.0 ohms/less: faulty ecu connection or faulty eui wiring harness connection or faulty ecu either measurements greater than 2.0 ohms: faulty eui harness in head ctm188 (20mar01) 04-160-247 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=435 trouble code diagnostics&tests 04 160 248 dpsg,rg40854,234 –19–30jun99–1/1 level 6 ecu - dtc spn 656 fmi 6 cylinder #6 eui circuit shorted rg10391 –19–23nov99 important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. eui (electronic unit injector) ? the fuel in 10.5 l&12.5 l engines is delivered by 6 (one for each cylinder) electronic unit injectors (euis). the euis are mounted in they cylinder head, under the valve cover, so that they spray directly into the center of the cylinder bore. each eui is an injection pump&injector combined, operating at much higher pressures than standard in-line or rotary injection pumps. the ecu controls the start of injection&the amount of fuel injected by turning the solenoid in the eui valve housing on&off which in turn opens&closes the eui spill valve. ? power is supplied to the euis for cylinders 1, 2, and 3 by a common wire,&to the euis for cylinders 4, 5,&6 by a different common wire. the ecu energizes&deenergizes the solenoids of individual euis by closing&opening the individual eui ground circuits. dtc spn 656 fmi 6 will set if: ? the ecu detects an open in the cylinder #6 eui circuit. if dtc spn 656 fmi 6 sets, the following will occur: ? cylinder #6 eui will not fire. ctm188 (20mar01) 04-160-248 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=436 trouble code diagnostics&tests ouo1004,0000cbf –19–08jan01–1/1 level 6 ecu - dtc spn 656 fmi 6 cylinder #6 eui circuit shorted - continued 04 160 249 – – –1/1 level 6 ecu - dtc spn 656 fmi 6 cylinder #6 eui circuit shorted diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of the 48-way ecu connector and the eui harness connector (located at the rear of the cylinder head) looking for dirty, damaged,/poorly positioned terminals. – – –1/1 1 intermittent fault test important: if dtcs spn 611 fmi 3, spn 611 fmi 4,/spn 627 fmi 1 are active, repair those dtcs first note: for wiring&theory of operation information, see dtc spn 656 fmi 6 cylinder #6 eui circuit shorted supporting information. 1. ignition on, engine off 2. using the dst, monitor dtcs on the active code display parameter 3. make note of any dtcs, then clear all dtcs 4. ignition on, engine running 5. using the dst, monitor dtcs on the active code display parameter spn 656 fmi 6 reoccurs: go to 2 spn 656 fmi 6 doesn’t reoccur: problem is intermittent. if no other codes are present, see intermittent fault diagnostics, earlier in this group. ctm188 (20mar01) 04-160-249 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=437 trouble code diagnostics&tests 04 160 250 – – –1/1 2 short in eui wiring harness test note: for wiring&theory of operation information, see dtc spn 656 fmi 6 cylinder #6 eui circuit shorted supporting information. 1. ignition off caution: possible strong electric shock hazard if engine is cranking or running 2. disconnect 18-terminal half of 48-way ecu connector 3. disconnect eui wiring harness connector at rear of cylinder head 4. using a multimeter, measure resistance between terminal e in the harness end of the eui wiring connector and: ? terminal c in the harness end of the eui wiring connector ? terminal f in the harness end of the eui wiring connector both measurements greater than 20,000 ohms: go to 3 either measurement less than 20,000 ohms: short in ecu wiring harness – – –1/1 3 cylinder 6 eui test note: for wiring&theory of operation information, see dtc spn 656 fmi 6 cylinder #6 eui circuit shorted supporting information. 1. remove rocker arm cover 2. disconnect electrical connections to cylinder 6 eui&a known good eui 3. using a multimeter measure resistance between: ? the two terminals on cylinder 6 eui ? the two terminals on the known good eui 4. compare the measurements between the two euis note: because eui resistance varies with temperature, a comparison is used to compensate for the effects of temperature. typical eui resistance should be 1.0-1.8 ohms difference between measurements 0.2 ohms/less: go to 4 difference between measurements greater than 0.2 ohms: faulty cylinder 6 eui – – –1/1 4 eui wiring harness in cylinder head test note: for wiring&theory of operation information, see dtc spn 656 fmi 6 cylinder #6 eui circuit shorted supporting information. 1. ignition off 2. keep cylinder 6 eui wires disconnected from eui 3. keep eui wiring harness connector at rear of cylinder head disconnected 4. using a multimeter, measure resistance between both of cylinder 6 eui harness eyelets greater than 20,000 ohms: faulty ecu connection or faulty eui wiring harness connection or faulty ecu less than 20,000 ohms: faulty eui wiring harness ctm188 (20mar01) 04-160-250 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=438 trouble code diagnostics&tests 04 160 251 ctm188 (20mar01) 04-160-251 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=439 trouble code diagnostics&tests 04 160 252 dpsg,rg40854,317 –19–26aug99–1/1 level 6 ecu - dtc spn 970 fmi 2 auxiliary engine shutdown switch signal invalid rg10663 –19–19dec00 note: wiring diagram shows tractor engine applications only. important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. dtc spn 970 fmi 2 will set if: ? the ecu reads an input voltage from the application’s controller to be less than 0.5 volts or greater than 2.5 volts. if dtc spn 970 fmi 2 sets, the following will occur: ? the ecu will shut the engine down. ctm188 (20mar01) 04-160-252 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=440 trouble code diagnostics&tests ouo1004,0000cc0 –19–08jan01–1/1 level 6 ecu - dtc spn 970 fmi 2 auxiliary engine shutdown switch signal invalid - continued – – –1/1 level 6 ecu - dtc spn 970 fmi 2 auxiliary engine shutdown switch signal invalid diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of 60-way ecu connector looking for dirty, damaged,/poorly positioned terminals. 04 160 253 – – –1/1 1 intermittent fault test note: for wiring&theory of operation information, see dtc spn 970 fmi 2 auxiliary engine shutdown switch signal invalid supporting information. 1. ignition on, engine off 2. using the dst, monitor dtcs on the active code display parameter 3. make note of any dtcs, then clear all dtcs 4. ignition on, engine running 5. using the dst, monitor dtcs on the active code display parameter spn 970 fmi 2 reoccurs: go to 2 spn 970 fmi 2 doesn’t reoccur: problem is intermittent. if no other codes are present, see intermittent fault diagnostics, earlier in this group. – – –1/1 2 other controller dtc test note: for wiring&theory of operation information, see dtc spn 970 fmi 2 auxiliary engine shutdown switch signal invalid supporting information. check another controller for related dtcs. note: auxiliary shutdown signal originates from another controller. controller reports no related dtcs: go to 3 controller has related dtcs: refer to diagnostic procedures for controller. repair cause of dtc and retest. – – –1/1 3 controller test note: for wiring&theory of operation information, see dtc spn 970 fmi 2 auxiliary engine shutdown switch signal invalid supporting information. 1. ignition off 2. disconnect 60-way ecu connector 3. ignition on 4. using a multimeter, measure voltage between terminal p3 in the harness end of the 60-way ecu connector&a good chassis ground less than 0.5 v or greater than 2.5v: go to 4 between 0.5 v&2.5v: wrong ecu for the vehicle or faulty ecu connector or faulty ecu or faulty auxiliary shutdown signal source controller ctm188 (20mar01) 04-160-253 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=441 trouble code diagnostics&tests – – –1/1 4 open in auxiliary shutdown signal circuit test note: for wiring&theory of operation information, see dtc spn 970 fmi 2 auxiliary engine shutdown switch signal invalid supporting information. 1. ignition off 2. 60-way ecu connector still disconnected 3. obtain wiring information for this application&determine the source of the auxiliary shutdown signal 4. disconnect the connector that outputs the shutdown signal 5. using a multimeter, measure the resistance between terminal p3 of the 60-way ecu connector&the originating shutdown signal terminal 5 ohms/less: go to 5 greater than 5 ohms: open in auxiliary shutdown signal circuit 04 160 254 – – –1/1 5 short in auxiliary shutdown signal circuit test note: for wiring&theory of operation information, see dtc spn 970 fmi 2 auxiliary engine shutdown switch signal invalid supporting information. 1. ignition off 2. using a multimeter measure resistance between terminal p3 in the harness end of the 60-way ecu connector and: ? all other terminals in that connector ? a good chassis ground all measurements greater than 2000 ohms: faulty signal source controller wiring or faulty auxiliary shutdown controller connector or faulty auxiliary shutdown signal source controller any measurement less than 2000 ohms: short in auxiliary shutdown signal circuit ctm188 (20mar01) 04-160-254 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=442 trouble code diagnostics&tests 04 160 255 ctm188 (20mar01) 04-160-255 p, owertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=443 trouble code diagnostics&tests 04 160 256 dpsg,rg40854,318 –19–26aug99–1/1 level 6 ecu - dtc spn 970 fmi 31 auxiliary engine shutdown switch active rg10653 –19–19dec00 important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. auxiliary engine shutdown switch ? on oem applications, the engine shutdown switch is a normally open switch. when the property being measured exceeds a certain value, the switch will close. when the switch is closed, the voltage is grounded, which will cause the ecu to shutdown the engine. dtc spn 970 fmi 31 will set if: ? the ecu does not read an input voltage. if dtc spn 970 fmi 31 sets, the following will occur: ? the ecu will shut the engine down. ctm188 (20mar01) 04-160-256 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=444 trouble code diagnostics&tests 04 160 257 ctm188 (20mar01) 04-160-257 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=445 trouble code diagnostics&tests 04 160 258 dpsg,rg40854,319 –19–26aug99–1/1 level 6 ecu - dtc spn 971 fmi 31 external fuel derate switch active rg10654 –19–19dec00 important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. external fuel derate switch on oem applications, the external derate switch is a normally open switch. when property being measured exceeds a certain value, t, he switch will close. when the switch is closed, the voltage , is grounded, which will cause the ecu to derate the engine. dtc spn 达州JohnDeere电子燃油泵AL155607哪里买,沈阳约翰迪尔拖拉机发动机副线束厂家供货,和田约翰迪尔RE501578修理包多少钱,西安约翰迪尔发动机高压油泵总成价格行情,普洱强鹿凸轮轴铜衬套R87561哪家买,海北约翰迪尔挖掘机止推片公司,安庆强鹿T26321凸轮轴上衬套多少钱,锦州约翰迪尔柴油机进气门R93308厂家批发,合肥强鹿输油泵RE517230价格行情,安顺强鹿柴油机RE504836机油滤清器批发价,沈阳约翰迪尔拖拉机发动机副线束代理商,泸州JohnDeere气门座圈R501640哪里买,黄石约翰迪尔曲轴RE534314的价格,海北JohnDeere排气门异管RE518083公司,971 fmi 31 will set if: ? the ecu does not read an input voltage. if dtc spn 971 fmi 31 sets, the following will occur: ? the ecu will derate the engine. the amount of derate is dependent on the application. ctm188 (20mar01) 04-160-258 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=446 trouble code diagnostics&tests 04 160 259 dpsg,rg40854,487 –19–25jan00–1/1 level 6 ecu - dtc spn 1109 fmi 31 engine shutdown warning engine shutdown warning: this code informs the operator that the ecu will shut the engine down because it has detected a condition such as low fuel pressure, water in fuel, low oil pressure, high engine coolant temperature, ecu error or low coolant level. if the ecu is programmed with engine protection with shutdown, the ecu has shut the engine down within 30 seconds. prior to shutdown, the engine will be derated. dtc spn 1109 fmi 31 will set if: ? the ecu senses a coolant temperature of 115 °c (239 °f) (dtc spn 110 fmi 1 will also be present). note: temperature value shown applies to oem engine applications. other applications may have the same/a similar temperature value. refer to the machine manual for high coolant temperature value. ? the ecu senses an oil pressure below the shutdown value set point in the ecu (dtc spn 100 fmi 1 will also be present). ? the ecu detects water in fuel above a quantity for an extended period of time by the ecu (dtc spn 97 fmi 0 will also be present). ? the ecu detects a fuel pressure below the shutdown value set point in the ecu (dtc spn 94 fmi 1 will also be present). ? the ecu detects a loss of coolant that is above the shutdown set point in the ecu (dtc spn 111 fmi 1 will also be present). ? the ecu detects an ecu error (dtc spn 629 12 or 13 will also be present). if dtc spn 1109 fmi 31 sets, the following will occur: ? if the ecu has engine KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

1 RE500834 ENGINE CONTROLLER 1 -028473 X (MARKED RE66614) (SUB RE504996)

RE501899 ENGINE CONTROLLER 1 028474-091161 X (MARKED RE66614 OR RE502404) (SUB

RE504996)

RE504996 ENGINE CONTROLLER 1 -091161 X (MARKED RE502404)

RE503410 ENGINE CONTROLLER 1 091162-114589 X (MARKED RE502404)

RE507476 ENGINE CONTROLLER 1 114590- X (MARKED RE502404)

2A RE30697 WIRING HARNESS 1 -028473 X

2B RE500664 WIRING HARNESS 1 028474- X

3A RE30711 MODULE 1 -028473 X

3B AT157679 DIODE 1 028474- X

4 RE152494 SWITCH 1 028474- X

5 RE151433 COOLANT TEMPERATURE SENSOR 1 028474- X

6 RE56009 ENGINE OIL PRESS. SENSOR 1 028474- X

7 R76337 WASHER 1 028474- X

8 R77673 O-RING 1 028474- X

9 .. SWITCH NA X (SUB FOR AH148258)

10 .. WIRING HARNESS NA X

11 19H1936 CAP SCREW 1 X 3/8" X 3/4"

12 24H1305 WASHER 1 X 13/32" X 13/16" X 0.065"

13 T13814 CLAMP 1 X

KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

1 RE500811 ENGINE CONTROLLER 1 -028473 X (MARKED RE502404) (SUB RE504988)

RE503434 ENGINE CONTROLLER 1 028474-091884 X (MARKED RE502404) (SUB RE504997)

RE504997 ENGINE CONTROLLER 1 -091884 X (MARKED RE502404)

RE507478 ENGINE CONTROLLER 1 091884- X (MARKED RE502404)

RE501831 ENGINE CONTROLLER 1 X (A) (MARKED RE28320 OR RE502404) (SUB

FOR RE64455)

2A RE30697 WIRING HARNESS 1 -028473 X

2B RE500664 WIRING HARNESS 1 028474- X

3A RE30711 MODULE 1 -028473 X

3B AT157679 DIODE 1 028474- X

4 RE152494 SWITCH 1 028474- X

5 RE151433 COOLANT TEMPERATURE SENSOR 1 028474- X

6 RE56009 ENGINE OIL PRESS. SENSOR 1 028474- X

7 R76337 WASHER 1 028474- X

8 R77673 O-RING 1 028474- X

9 .. SWITCH NA X (SUB FOR AH148258)

10 .. WIRING HARNESS NA X

11 19H1936 CAP SCREW 1 X 3/8" X 3/4"

12 24H1305 WASHER 1 X 13/32" X 13/16" X 0.065"

13 T13814 CLAMP 1 X

(A) REMANUFACTURED

ECHANGE STANDARD

GENERAUEBERHOLT

RIGATTO

REFABRICADO POR

RENOVERAD

KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

1 .. HOLDER NA X X

2 T24210 O-RING 6 X X

3 R76358 O-RING 1 X X

4 14M7297 NUT 3 X X M5

5 12H296 WASHER 3 X X 0.216"

6 R67879 GASKET 1 X X

7 R53899 WASHER 1 X X

8 RE36151 CONTROL VALVE 1 X X

9 R53901 WASHER 1 X X

10 R63016 ADAPTER 1 X X

11 R67364 ELBOW FITTING 1 X X

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska