详细描述

麦克福斯约翰迪尔发动机零配件

约翰迪尔 6068T/H 6.8T/H 活塞(米)RE527039 排放 2 & 3

|

| |||||||||||||||||||||||||||

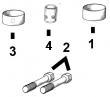

(1)1件组合式密封和穿套; 替换TRE59810,RE538097。

(2)在曲轴加工过程中必须保持正确的轴承轴颈半径,以确保正确操作。

(3)曲轴(m)R116076,直鼻。

(4)曲轴(m)R503470,锥形鼻。

(5)检查应用程序是否正确使用。

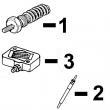

(6)线路连接都是线程化的。

(7)线路连接是一个软管倒钩& 一个线程。

(8)线路连接是两个软管倒钩。

(9)机器分体式和断裂式分体式连杆均可用于同一台发动机,但每个连杆必须使用正确的连杆螺栓。

强鹿JOHN DEERE柴油机配件、发动机配件、发电机组:

6090HFU75、6068HFU74、6090HFU84、4024TF220、6090HF485 6081HF001、6081AF001、6081TF001、4039DF004、6068HF252、4039DF005、4039DF008、6076TF010、6059TF001、4045HF275、RG6125、6135H458、4045DFM70, 4045TFM75

强鹿JOHN DEERE柴油机配件、发动机配件、发电机组:

6068TFM75, 6068TFM76、6068HF275、6125HF070\6125AF001,4039DFM、6125HF070、6135HF475-2、6135HF475-3 RE68345、 RE53307、RE62240、RE533095、RE502513、RE38009、R30402、RE517180、RE530107、RE62240、P524837、RE60021、RE507236、RE59588、RE549153、RE530870、SE501610、SE501609、RE70960、RE533501、RE533608、AR50041、RE515409