详细描述

麦克福斯约翰迪尔发动机零配件

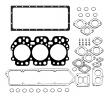

约翰迪尔 3029 2.9T 活塞(米) RE500211

|

| ||||||||||||||||||||||||||||||

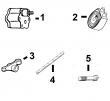

(1)螺旋齿轮。

(2)将所有R78558带帽螺丝替换为带法兰头帽螺丝TR85363。

(3)套管安装后,在装配活塞销之前,应使机器套管符合连杆的形状。

(4)套件包含TT20094斜齿轮转换为TRE50979曲轴。

(5)使用机器拆分连杆使用TR80033并使用断裂连杆TR501124。

(6)(m)R73604。

(7)(m)R100812,(m)R127337,(m)R127918,(m)R55164。

(8)与断裂分体连杆一起使用。

(9)检查您的应用程序是否正确使用。

(10)凸轮轴有一个40毫米宽的前轴承轴颈,用于转速计驱动的后部压力机,它将取代前轴承轴颈较窄的早期凸轮轴而没有任何问题。取代凸轮轴标志T20015,T20016,R79643,R106957和RE522311。

强鹿JOHN DEERE柴油机配件、发动机配件、发电机组:

C085003、C085004、ECB105012、C105003、AF1913、AF4539、C105004、RE533026、H0000351、ECC105017、C105003、ECC105028、ECC065003、B125003、ECB125011

dpsg,rg41221,40 –19–19may00–1/1 4 5l/6 8l - c1 - engine coolant temperature above normal symptom problem solution 4 5l/6 8l - c1 - engine coolant lack of coolant in cooling system fill cooling system to proper level temperature above normal radiator core and/or side screens clean radiator as required dirty engine overloaded reduce engine load too low crankcase oil level fill crankcase to proper oil level loose/defective fan belt replace/tighten fan belt as required premature belt wear/belt flies off check pulley alignment refer to pulley dtac solution no k001230 for realignment on some oem engines defective thermostat(s) test thermostat opening temperature; replace thermostats as required see inspect thermostat&test opening temperature later in this group damaged cylinder head gasket replace cylinder head gasket see check for head gasket failures later in this group defective coolant pump replace coolant pump see remove water pump in group 070 in section 2 of this manual defective radiator cap replace radiator cap as required see pressure test cooling system&radiator cap later in this group ctm104 (11jul02) 04-150-9 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=479 observable diagnostics&tests dpsg,rg41221,41 –19–19may00–1/1 4 5l/6 8l - c2 - engine coolant temperature below normal symptom problem solution 4 5l/6 8l - c2 - engine coolant defective thermostat(s) test thermostats; replace temperature below normal thermostats as required see inspect thermostat and test opening temperature later in this group 04 150 10 dpsg,rg41221,42 –19–19may00–1/1 4 5l/6 8l - c3 - coolant in oil/oil in coolant symptom problem solution 4 5l/6 8l - c3 - coolant in oil/faulty cylinder head gasket look for signs of head gasket failure oil in coolant see check for head gasket failures later in this group faulty oil cooler remove&inspect engine oil cooler see remove, inspect, and install oil cooler in group 060 in section 2 of this manual leaking cylinder liner seals remove&inspect cylinder liners see visually inspect cylinder liners in group 030 in section 2 of this manual cracked cylinder head/block locate crack; repair/replace components as required ctm104 (11jul02) 04-150-10 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=480 observable diagnostics&tests 04 150 11 rg,105,jw7652 –19–19jun02–1/3 test engine compression pressure important: compression pressures are affected by the cranking speed of the engine before beginning test, ensure that batteries are fully charged&injection nozzle area is thoroughly cleaned 1 start engine&run at rated speed until it warms up to normal operating temperature (from a cold start, operate engine 10—15 minutes at slow idle ) 2 shut off engine&procede to connections for two-valve/four-valve head engines as required two-valve head engines 1 shut off fuel supply&remove fuel injection nozzles see ctm207 (mechanical fuel systems), ctm170 (electronic fuel systems with bosch vp44 pump), ctm331 (electronic fuel systems with stanadyne de10 pump)/ctm284 (electronic fuel systems with delphi dp201 pump) continued on next page ctm104 (11jul02) 04-150-11 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=481 observable diagnostics&tests 04 150 12 rg,105,jw7652 –19–19jun02–2/3 rg7769 –un–15jan98 compression tester in nozzle bore (two-valve head shown) rgcd30432 –un–31oct97 rg9139 –un–18may98 compression tester adapters (two-valve head shown) a—19 58—90 578 adapter b—r73788 nozzle spacer c—r92352 nozzle seal d—holding plate e—fkm10022 test gauge 2 install jt016791 adapter with o-ring (or d14550ba2 adapter) in injection nozzle bore use jt02017 holding clamp1 to hold jt01679 adapter in position install hold-down screw in clamp&tighten screw to 37 n?m (27 lb-ft) attach jt016821 test gauge (or d14547ba2) to adapter note: if using fkm10021 compression test set, install 19 58—90 578 adapter (a) in injection nozzle bore with r73788 nozzle spacer (b)&two r92352 nozzle seals (c) use holding plate (d) to secure then attach fkm10022 test gauge (e) to adapter four-valve head engines 1 shut off fuel supply&remove glow plugs see ctm220 (level 11 electronic fuel systems with denso high pressure common rail) 2 install a suitable m10 x 1 0 adapter with thread sealer to cylinder head&install compression gauge to adapter do not tighten adapter to more than glow plug torque specification specification glow plug—torque 15 n?m (11 lb-ft) compression test 1 push throttle lever to “stop” position turn crankshaft for 10—15 seconds with starter motor (minimum cranking speed—150 rpm cold/200 rpm hot) 2 compare readings from all cylinders compression pressure must be within specification specification engine compression pressure test—engine compression pressure 2379—2792 kpa (24—28 bar) (345—405 psi) maximum difference between cylinders 350 kpa (3 5 bar) (50 psi) 1 part of jt01674 compression test set 2part of d14546ba compression test set ctm104 (11jul02) 04-150-12 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=482 continued on next page observable diagnostics&tests 04 150 13 rg,105,jw7652 –19–19jun02–3/3 note: pressure given was taken at 183 m (600 ft) above sea level a 3 6 percent reduction in gauge pressure will result for each additional 300 m (1000 ft) rise in altitude all cylinders within an engine should have approximately the same pressure there should be less than 340 kpa (3 4 bar) (50 psi) difference between cylinders 3 if pressure is much lower than shown, remove gauge and apply oil to ring area of piston through injection nozzle/glow plug bore do not use too much oil do not get oil on the valves 4 test compression pressure again if pressure is high, worn/stuck rings are indicated, replace piston rings/install new piston&liner set as needed (see section 02, group 030 ) if pressure is low, valves could be worn/sticking recondition cylinder head as required (see section 02, group 020 ) 5 measure compression pressure in all remaining cylinders&compare readings recondition cylinders and valves as required ctm104 (11jul02) 04-150-13 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=483 observable diagnostics&tests 04 150 14 dpsg,ouo1004,164 –19–26apr00–1/1 test engine cranking speed rg9444 –un–23jul98 engine cranking speed test important: cranking speed specifications above are for oem engines only see machine technical manual for other applications make sure that batteries are fully charged before performing this test 1 disable the fuel supply system at the injection pump so fuel delivery is in the off position 2 if not using the machine tachometer, install a photo tach/time trac? 3 crank the engine for 15 seconds&record engine speed 4 compare recorded engine speed to chart above cranking speed should meet/exceed specified engine rpm for a given ambient air temperature for example, at 29°c (85°f) ambient air temperature, cranking speed should be at least 200 rpm if cranking speed is below specifications, check the following: ? starting system problems (low battery, loose or defective wiring, defective starter, etc ) ? excessive engine loads (hydraulic pumps/thick oil, thick engine oil, etc ) time trac is a registered trademark of stanadyne automotive corp ctm104 (11jul02) 04-150-14 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=484 observable diagnostics&tests 04 150 15 rg,100,jw7644 –19–12nov99–1/1 dynamometer test important: dynamometers should be periodically checked for accuracy and calibrated as necessary note: high elevations may affect engine performance (see effects of altitude and temperature on engine performance, in section 06, group 210 ) 1 connect engine to dynamometer using manufacturer’s instructions 2 operate engine at one-half load until coolant and crankcase oil temperatures are up to normal operating range 3 run engine at fast idle 4 gradually increase load on engine until speed is reduced to rated speed rpm note: refer to appropriate machine technical manual for average power ratings of specific applications allow ±5% for minimum and maximum power 5 read horsepower on dynamometer&record reading over a period of several minutes after engine stabilizes 6 compare readings taken with power rating level for your engine application, as listed in section 06, group 210 ctm104 (11jul02) 04-150-15 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=485 observable diagnostics&tests 04 150 16 dpsg,ouo1004,114 –19–23may00–1/1 engine oil consumption all engines consume some oil the consumption rate depends on loading, design of key parts&engine condition since fuel consumption is an indicator of operating power levels, fuel used versus oil consumed is a critical factor in analyzing oil consumption oil consumption should be measured over a 100-hour period long-term oil consumption (three oil drain intervals after the engine is broken in) with consumption rates poorer than 400:1 (100 gallons of fuel&1 quart of oil) indicates a need to monitor/investigate suggested steps would be: ? check for signs of ingested dust/perform an oilscan? test to check for silicon ? check for proper crankcase oil fill level ? perform compression test to find low compression cylinders ? remove head&inspect for glazed/worn liners ? inspect pistons for carbon deposits in the ring land grooves ? measure valve stem od&valve guide id to determine clearance note: ring gap alignment does not identify the leak source intake valves do not have valve stem seals, and some oil deposits on the valve stem tulip are normal when changing to a premium oil such as torq-gard supreme? plus-50?, little oil consumption change is expected, although a small percentage of engines may experience a noticeable change in consumption rates this may be due to the following: ? the previous oil may have left deposits on internal components use of plus-50? oil will cause different chemical reactions in those deposits the time required for the engine to regain the previous oil consumption rate will vary from one to three normal drain intervals ? torq-gard supreme? plus-50? contains a high-performance anti-oxidant along with other additives resulting in the oil remaining in the specified viscosity grade throughout the recommended drain interval api oil grades cd, ce, and cf-4 universal engine oils do not provide this oxidation resistance which results in more rapid thickening increased oil viscosity can reduce oil consumption oilscan is a trademark of deere & company torq-gard supreme is a registered trademark of deere & company plus-50 is a registered trademark of deere & company ctm104 (11jul02) 04-150-16 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=486 observable diagnostics&tests 04 150 17 rg,105,jw7651 –19–21nov97–1/2 check engine oil pressure rg7484b –un–04nov97 main oil gallery plug removal tool a—oil gallery plug 1 remove main oil gallery plug (a) using jdg782a oil gallery plug tool continued on next page ctm104 (11jul02) 04-150-17 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=487 observable diagnostics&tests 04 150 18 rg,105,jw7651 –19–21nov97–2/2 rg7770 –un–11nov97 pressure gauge to oil gallery port b—pressure gauge 2 attach pressure gauge (b) from jt05470 universal pressure test kit to oil gallery important: to achieve an accurate oil pressure reading, warm up engine crankcase oil to 105°c (220°f)/high oil pressure readings will occur 3 start engine&run at speeds given below 4 measure oil pressure&compare readings specification minimum oil pressure—no load at slow idle&93°c (200°f) oil temperature—minimum pressure 105 kpa (1 05 bar) (15 psi) minimum oil pressure—full load at rated speed&105°c (220°f) oil temperature— minimum pressure 275 kpa (2 75 bar) (40 psi) note: tolerance extremes&gauge fluctuations can result in the gauge reading up to 586 kpa (5 86 bar) 85 psi this is not detrimental to the engine the oil pressure regulating valve is designed so that adjustment of oil pressure should not be required 5 replace oil pressure regulating valve if oil pressure is not within specified range ctm104 (11jul02) 04-150-18 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=488 observable diagnostics&tests 04 150 19 rg,105,jw7650 –19–21nov97–1/1 check for excessive engine crankcase pressure (blow-by) rg9568 –un–22jul98 blow-by check a—breather tube excessive blow-by coming out of the crankcase breather tube (a) indicates that either the turbocharger (if equipped) seals are faulty/the piston rings&cylinder liners are not adequately sealing off the combustion chamber this is a comparative check that requires some experience to determine when blow-by is excessive run engine at high idle&check crankcase breather tube look for significant fumes and/or dripping oil coming out of the breather tube at fast idle, with no load if excessive blow-by is observed, perform the following to determine if the turbocharger (if equipped) is causing the blow-by: 1 remove the turbocharger oil drain line where it connects to the engine block&run line into a ***et 2 run engine at high idle, slightly loaded,&determine if boost pressure is forcing oil through the drain line check crankcase breather tube to determine if blow-by has decreased 3 if it appears that boost pressure is forcing oil through the drain line, and/or blow-by decreases with the drain line disconnected from block, replace the turbocharger, and retest ctm104 (11jul02) 04-150-19 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=489 observable diagnostics&tests 04 150 20 dpsg,ouo1004,225 –19–10jul98–1/1 check for turbocharger oil seal leak rg9440 –un–23jul98 turbocharger oil seal leak test a—crossover tube b—oil return line seals are used on both sides of the turbocharger rotor assembly the seals are used to prevent exhaust gasses and air from entering the turbocharger housing oil leakage past the seals is uncommon but can occur a restricted/damaged turbocharger oil return line can cause the housing to pressurize, causing oil to leak by the seals additionally, intake/exhaust restrictions can cause a vacuum between the compres*** and turbocharger housing, causing oil to leak by the seals 1 remove exhaust pipe (shown removed)&crossover tube (a) 2 inspect the turbine casing&crossover tube for evidence of oil leakage if oil leakage is present, perform the following: ? inspect turbocharger oil return line (b) for kinks or damage replace if necessary ? check the air intake filter, hoses,&crossover tube for restrictions ? check the exhaust system for restrictions to include position of exhaust outlet 3 perform necessary repairs&repeat test ctm104 (11jul02) 04-150-20 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=490 observable diagnostics&tests 04 150 21 rg,105,jw7648 –19–21nov97–1/1 inspect thermostat&test opening temperature rg5971 –un–23nov97 test thermostat opening temperature visually inspect thermostat for corrosion/damage replace as necessary test thermostat as follows: caution: do not allow thermostat or thermometer to rest against the side/bottom of container when heating water either may rupture if overheated 1 remove thermostats (see procedure in section 02, group 070 ) 2 suspend thermostat&a thermometer in a container of water 3 stir the water as it heats observe opening action of thermostat&compare temperatures with specification given in chart below note: due to varying tolerances of different suppliers, initial opening&full open temperatures may vary slightly from specified temperatures thermostat test specifications rating initial opening (range) full open (nominal) 71°c (160°f) 69—72°c (156—162°f) 84°c (182°f) 77°c (170°f) 74—78°c (166—172°f) 89°c (192°f) 82°c (180°f) 80—84°c (175—182°f) 94°c (202°f) 89°c (192°f) 86—90°c (187—194°f) 101°c (214°f) 90°c (195°f) 89—93°c (192—199°f) 103°c (218°f) 92°c (197°f) 89—93°c (193—200°f) 105°c (221°f) 96°c (205°f) 94—97°c (201—207°f) 100°c (213°f) 99°c (210°f) 96—100°c (205—212°f) 111°c (232°f) 4 remove thermostat&observe its closing action as it cools in ambient air the thermostat should close completely closing action should be smooth&slow 5 if any thermostat is defective on a multiple thermostat engine, replace all thermostats ctm104 (11jul02) 04-150-21 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=491 observable diagnostics&tests 04 150 22 rg,105,jw7649 –19–21nov97–1/2 pressure test cooling system&radiator cap rg6557 –un–20jan93 pressure testing radiator cap rg6558 –un–20jan93 pressure testing radiator caution: explosive released fluids from pressurized cooling system can cause serious burns shut off engine only remove filler cap when cool enough to touch with bare hands slowly loosen cap to first stop to relieve pressure before removing completely test radiator cap: 1 remove radiator cap&attach to d05104st pressure pump as shown 2 pressurize cap to the following specification1 two-valve head engines&4 5 l four-valve head engines— specification radiator cap2—holding pressure (10 second minimum hold) 70 kpa (0 7 bar) (10 psi) minimum 6 8 l four-valve head engines—specification radiator cap3—holding pressure (10 second minimum hold) 100 kpa (1 0 bar) (15 psi) minimum gauge should hold pressure for 10 seconds within the normal range if cap is acceptable if ga, uge does not hold pressure, replace radiator cap 3 remove the cap from gauge, turn it 180°, and retest cap this will verify that the first measurement was accurate test cooling system: note: engine should be warmed up to test overall cooling system 1 allow engine to cool, then carefully remove radiator cap 1test pressures recommended are for all deere oem cooling systems on specific vehicle applications, test cooling system and pressure cap according to the recommended pressure for that vehicle 26068hf275 industrial oem with vp44 pump use a radiator cap with a pressure specification 100 kpa (1 0 bar) (15 psi) minimum 36068hf475 for gen-set applications use a radiator cap with 70 kpa (0 7 bar) (10 psi) minimum ctm104 (11jul02) 04-150-22 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=492 continued on next page observable diagnostics&tests 04 150 23 rg,105,jw7649 –19–21nov97–2/2 2 fill radiator with coolant to the normal operating level important: do not apply excessive pressure to cooling system doing so may damage radiator&hoses 3 connect gauge&adapter to radiator filler neck pressurize cooling system to specification listed for radiator cap 1, using d05104st pressure pump 4 with pressure applied, check all cooling system hose connections, radiator,&overall engine for leaks if leakage is detected, correct as necessary and pressure test system again if no leakage is detected, but the gauge indicated a drop in pressure, coolant may be leaking internally within the system/at the block-to-head gasket 1test pressures recommended are for all deere oem cooling systems on specific vehicle applications, test cooling system and pressure cap according to the recommended pressure for that vehicle ctm104 (11jul02) 04-150-23 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=493 observable diagnostics&tests 04 150 24 rg,105,jw7657 –19–23may00–1/4 check for head gasket failures rg6432 –un–03nov97 diagnosing head gasket joint failures a—combustion sealing area b—oil sealing areas c—coolant sealing areas note: booklet db1119—cylinder head gasket failures for 6466&6076 engines can be used as a guide for diagnosing head gasket failures on powertech? 4 5 l&6 8 l engines however, use specifications provided in this manual (ctm104) head gasket failures generally fall into three categories: ? combustion seal failures ? coolant seal failures ? oil seal failures combustion seal failures occur when combustion gases escape between cylinder head&head gasket combustion flange,/between combustion flange and cylinder liner leaking combustion gases may vent to an adjacent cylinder, to a coolant/oil passage, or externally coolant/oil seal failures occur when oil/coolant escapes between cylinder head&gasket body, or between cylinder block&gasket body the oil or coolant may leak to an adjacent coolant/oil passage, or externally since oil&coolant passages are primarily on right-hand (camshaft) side of engine, fluid leaks are most likely to occur in that area follow these diagnostic procedures when a head gasket joint failure occurs/is suspected 1 before starting/disassembling engine, conduct a visual inspection of machine?e any of the following: ? oil/coolant in head gasket seam,/on adjacent surfaces especially right rear corner of gasket joint ? displacement of gasket from normal position ? discoloration/soot from combustion gas leakage ? leaking radiator, overflow tank,/hoses ? leaking coolant from coolant pump weep hole ? damaged/incorrect radiator, fan,/shroud ? obstructed air flow/coolant flow powertech is a trademark of deere & company ctm104 (11jul02) 04-150-24 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=494 continued on next page observable diagnostics&tests 04 150 25 rg,105,jw7657 –19–23may00–2/4 ? worn/slipping belts ? damaged/incorrect pressure cap ? presence of oil in coolant ? low coolant levels/improper coolant ? unusually high/low oil levels ? oil degradation, dilution,/contamination ? incorrectly specified injection pump ? indications of fuel/timing adjustments ? unburned fuel/coolant in exhaust system 2 obtain coolant&oil samples for further analysis 3 start&warm up engine if it can be safely operated examine all potential leakage areas again as outlined previously using appropriate test&measurement equipment, check for the following: ? white smoke, excessive raw fuel,/moisture in exhaust system ? rough, irregular exhaust sound,/misfiring ? air bubbles, gas trapped in radiator/overflow tank ? loss of coolant from overflow ? excessive cooling system pressure ? coolant overheating ? low coolant flow ? loss of cab heating (air lock) 4 shut engine down recheck crankcase, radiator, and overflow tank for any significant differences in fluid levels, viscosity,/appearance 5 compare your observations from above steps with the diagnostic charts earlier in this group if diagnostic evaluations provide conclusive evidence of combustion gas, coolant,/oil leakage from head gasket joint, the cylinder head must be removed for inspection and repair of gasket joint components combustion seal leakage symptoms: ? exhaust from head gasket crevice ? air bubbles in radiator/overflow tank ? coolant discharge from overflow tube ? engine overheating ? power loss ctm104 (11jul02) 04-150-25 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=495 continued on next page observable diagnostics&tests 04 150 26 rg,105,jw7657 –19–23may00–3/4 ? engine runs rough ? white exhaust smoke ? loss of cab heat ? gasket section dislodged, missing (blown) ? coolant in cylinder ? coolant in crankcase oil ? low coolant level possible causes: ? insufficient liner standout ? excessive liner standout differential between cylinders ? low head bolt clamping loads ? rough/damaged liner flange surface ? cracked/deformed gasket combustion flange ? out-of-flat/damaged/rough cylinder head surface ? missing/mislocated gasket fire ring ? block cracked in liner support area ? excessive fuel delivery ? advanced injection pump timing ? hydraulic/mechanical disturbance of combustion seal note: cracked cylinder head/liners may also allow combustion gas leakage into coolant coolant seal leakage symptoms: ? coolant discharge from head gasket crevice ? coolant in crankcase oil ? low coolant level ? high oil level ? coolant discharge from crankcase vent possible causes: ? excessive liner standout ? excessive liner standout differential between cylinders ? low head bolt clamping loads ? out-of-flat/damaged/rough block surface ? out-of-flat/damaged/rough cylinder head surface ? oil/coolant overheating ? cracks/creases in gasket body surfaces ? damage/voids in elastomer beading oil seal leakage ctm104 (11jul02) 04-150-26 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=496 continued on next page observable diagnostics&tests 04 150 27 rg,105,jw7657 –19–23may00–4/4 symptoms: ? oil discharge from head gasket crevice ? oil in coolant ? low crankcase oil level ? reduced oil to rocker arms (noisy) possible causes: ? excessive liner standout ? excessive liner standout differential between cylinders ? low head bolt clamping loads ? out-of-flat/damaged/rough block surface ? out-of-flat/damaged/rough cylinder head surface ? oil/coolant overheating ? cracks/creases in gasket body surfaces ? damage/voids in elastomer beading ? damaged/missing o-ring seal at oil port to rocker arms note: defective oil cooler may also allow oil leakage into coolant rg,100,jw7635 –19–15dec99–1/3 check&service cooling system rg7990 –un–14nov97 inspect coolant pump weep hole a—weep holes 1 remove trash that has accumulated on/near radiator 2 visually inspect entire cooling system&all components for leaks/damage repair/replace as necessary 3 inspect radiator hoses for signs of leakage/rot replace hoses as necessary 4 inspect the coolant pump weep hole (a) for any restrictions 5 insert a heavy gauge wire deep into weep hole to make sure hole is open ctm104 (11jul02) 04-150-27 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=497 continued on next page observable diagnostics&tests 04 150 28 rg,100,jw7635 –19–15dec99–2/3 ts281 –un–23aug88 cooling system safety rg7615b –un–06nov97 check thermostat housing rg7614b –un–06nov97 check thermostat rg7991 –un–14nov97 engine block coolant drain valve a—thermostat housing b—thermostat c—drain valve caution: do not drain coolant until it has cooled below operating temperature always loosen block drain valve slowly to relieve any excess pressure 6 remove&check thermostat(s) (b) (see test thermostats in section 02, group 070 ) important: whenever the aluminum timing gear cover/coolant pump are replaced, the radiator should be completely drained by opening the radiator petcock and removing the lower radiator hose engines are now serviced with a coolant pump insert to decrease cavitation when removing the coolant pump, inspect the coolant pump cavity in the timing gear cover for excessive cavitation if engine has no coolant pump insert, install coolant pump insert (see install coolant pump in group 070 ) 7 drain coolant at drain valve (c)&flush cooling system (see flush&service cooling system in section 01, group 002 ) important: air must be expelled from cooling system when system is refilled loosen temperature sending unit fitting at rear of cylinder head/plug in thermostat housing (a) to allow air to escape when filling system retighten fitting/plug when all the air has been expelled 8 fill cooling system with recommended concentration of coolant, clean soft water,&inhibitors (see diesel engine coolant in section 01, group 002 ) 9 run engine until it reaches operating temperature check entire cooling system for leaks ctm104 (11jul02) 04-150-28 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=498 continued on next page observable diagnostics&tests rg,100,jw7635 –19–15dec99–3/3 10 after engine cools, check coolant level note: coolant level should be even with bottom of radiator filler neck 11 check system for holding pressure (see pressure test cooling system&radiator cap in this group ) 04 150 29 rg,100,jw7637 –19–21nov97–1/1 check air intake system rg7766a –un–10nov97 check air cleaner elements rg7618c –un–06nov97 check turbocharger air intake hoses a—secondary filter element b—primary filter element c—air intake hose(s) d—hose clamps 1 replace air cleaner primary filter element (b) replace secondary element (a) if primary element has holes in it 2 check condition of air intake hose(s) (c) replace hoses that are cracked, split,/otherwise in poor condition 3 check hose clamps (d) for tightness replace clamps that cannot be properly tightened this will help prevent dust from entering the air intake system which could cause serious engine damage ctm104 (11jul02) 04-150-29 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=499 observable diagnostics&tests dpsg,ouo1004,134 –19–26apr00–1/3 measure intake manifold pressure (turbocharger boost/power check) this test of turbocharger boost is also a good indicator of whether the engine is performing at full rated power 04 150 30 continued on next page ctm104 (11jul02) 04-150-30 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=500 observable diagnostics&tests 04 150 31 dpsg,ouo1004,134 –19–26apr00–2/3 rg7776 –un–11nov97 check turbocharger boost pressure rg7777 –un–11nov97 check turbocharger boost pressure a—intake manifold line b—pressure gauge important: if testing the engine with the air filter system removed, install jdg576 turbocharger shield to inlet of turbocharger note: on “h” engines, pressure reading should be taken at intake manifold after the aftercooler 1 disconnect line (a) from intake manifold&install the appropriate fitting from jde147 manifold pressure test kit/fkm10002 universal pressure test kit additional adapter fittings may be needed: m10 x 1 and m14 x 1 5 connect gauge (b)&hose assembly to fitting be sure all connections are tight important: engine speed&load should be stabilized before taking a gauge reading be sure that gauge works properly&familiarize yourself with the use of the gauge turbo-boost pressure checks are only a guide to determine if there is an engine problem (valve leakage, faulty nozzles, etc ) low pressure readings are not a conclusive reason for increasing injection pump fuel delivery pump adjustment should be within specifications as established by an authorized diesel repair station 2 before checking boost pressure, warm up engine to allow the lubricating oil to reach operating temperature important: on some vehicles, it may not be possible to meet the turbo boost pressure due to inability to get full load rated speed in these cases, see machine operation&test manual for the appropriate test method and pressure 3 place engine under full load at rated speed to make test ctm104 (11jul02) 04-150-31 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=501 continued on next page observable diagnostics&tests 04 150 32 dpsg,ouo1004,134 –19–26apr00–3/3 4 observe pressure reading on gauge compare readings with charts in section 06, group 210 boost pressure should be within ranges shown in charts when engine is developing rated power at full load rated speed 5 if boost pressure is too high, remove fuel injection pump&have it checked for high fuel delivery by an authorized diesel repair station if boost pressure is too low, check the following: ? restricted air filter elements ? restricted fuel filter elements ? incorrect fast idle adjustment ? incorrect injection pump timing ? exhaust manifold leaks ? intake manifold leaks ? faulty fuel transfer pump ? low compression pressure ? faulty fuel injection nozzles ? carbon build-up in turbocharger ? turbocharger compres***/turbine wheel rubbing housing ? low fuel injection pump fuel delivery ? restricted exhaust 6 after completing test, remove test equipment&fitting and reconnect line to intake manifold tighten securely ctm104 (11jul02) 04-150-32 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=502 observable diagnostics&tests 04 150 33 dpsg,ouo1004,222 –19–10jul98–1/1 check for intake&exhaust restrictions rg9560 –un–22jul98 intake/exhaust restriction check—two-valve head engine shown a—exhaust piping c—rain cap e—elbow f—connection b—muffler d—intake piping low power, low boost pressure,&excessive black exhaust smoke can be caused by an intake air or exhaust restriction 1 inspect the exhaust piping (a), the muffler (b), and the rain cap (c) for damage/any possible restrictions 2 inspect the intake piping (d), any elbows (e), and any connections (f) look for collapsed pipes, dented pipes&loose connections replace components as needed ctm104 (11jul02) 04-150-33 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=503 observable diagnostics&tests 04 150 34 dpsg,ouo1004,220 –19–26apr00–1/1 test for intake , air leaks t5906ap –un–23feb89 air intake leak test rg9148 –un–23jul98 air intake leak test c rg12402 –un–12jun02 air intake leak test - four valve head a—start aid line b—plug c—air temperature sen*** loose connections/cracks in the suction side of the air intake pipe can allow debris to be ingested into the engine causing rapid wear in the cylinders additionally, on turbocharged engines, compres*** damage may occur and cause an imbalance resulting in bearing failure air leaking from loose connections/cracks on the pressure side of the turbocharger can cause excessive smoke&low power note: the following test procedure requires that the air intake be sealed off to pressurize the system using a plastic bag to seal the air intake filter is used as an example caution: do not start engine during this test procedure plastic bag (or whatever material/object used to seal intake) can be sucked into the engine 1 remove air cleaner cover&main filter element 2 put a plastic bag over secondary filter element and install main element&cover 3 for two valve head engines, remove plug (b) from manifold/disconnect start aid line (a) from crossover tube (if equipped) 4 for four valve head engines, remove air temperature sen*** (c) from manifold 5 using a adapter, connect a regulated air source 6 pressurize air intake system to 13 8—20 7 kpa (0 13-0 21 bar) (2—3 psi) 7 spray soap&water solution over all connections from the air cleaner to the turbocharger/air inlet to check for leaks repair all leaks 8 remove plastic bag from filter element&reinstall element&cover ctm104 (11jul02) 04-150-34 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=504 observable diagnostics&tests 04 150 35 dpsg,ouo1004,288 –19–23jul98–1/1 check for exhaust air leaks (turbocharged engines) rg9576 –un–22jul98 exhaust leak check a—exhaust manifold gasket b—exhaust manifold c—turbocharger gasket1 exhaust leaks, upstream of the turbocharger, will cause the turbocharger turbine to rotate at a reduced speed resulting in low boost pressure, low power,&excessive black smoke important: avoid engine damage&failure there are two types of gaskets: single entry and dual entry single entry is completely open in the center&dual entry has a divider in the center do not interchange dual&single entry gaskets inspect the exhaust manifold gasket (a), the exhaust manifold (b),&the turbocharger gasket (c) for damage and any signs of leakage replace components as needed 1 there are two types of gaskets: single entry&dual entry single entry is completely open in the center&dual entry has a divider in the center do not interchange dual&single entry gaskets ctm104 (11jul02) 04-150-35 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=505 observable diagnostics&tests 04 150 36 dpsg,ouo1004,224 –19–10jul98–1/1 test turbocharger wastegate rg9147 –un–23jul98 wastegate check a—actuator fitting b—actuator rod 1 check hose to wastegate actuator for kinks/cracks replace if damaged 2 disconnect hose from wastegate actuator 3 connect a regulated air source to actuator fitting (a) 4 vary pressure to wastegate actuator from 62—83 kpa ( 62— 83 bar) (9—12 psi) actuator rod (b) should move in&out freely as pressure is varied if rod does not move freely, check wastegate adjustment (see adjust turbocharger wastegate actuator in section 02, group 080 ) rg,110,jw7671 –19–24nov97–1/1 test air filter restriction indicator switch rgt6188aq –un–19nov97 test air filter restriction indicator a—gauge b—tee fitting c—pipe nipple 1 remove air filter restriction indicator switch from air intake piping 2 install pipe nipple (c), tee fitting (b),&gauge (a) from d05022st water vacuum gauge kit into air filter restriction indicator hole install air filter restriction indicator into tee fitting 3 start engine&slowly cover the air cleaner inlet with a piece of paper/cardboard 4 air restriction indicator must show red at 5 6—6 8 kpa (56—68 bar) (22 7—27 3 in water) (1 6—2 0 in hg) vacuum if air restriction indicator shows red at any other value than listed above, install a new indicator ctm104 (11jul02) 04-150-36 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=506 section 05 tools&other materials contents page page group 170—repair tools&other materials group 180—diagnostic service tools engine rebuild essential tools 05-170-1 diagnostic essential tools 05-180-1 engine rebuild service equipment&diagnostic service equipment&tools 05-180-3 tools 05-170-2 engine rebuild other materials 05-170-3 group 190—dealer fabricated service tools cylinder head&valves essential tools how to make tools 05-190-1 (two-valve head) 05-170-3 dfrg3—cylinder liner holding fixture 05-190-1 cylinder head&valves service dfrg5—injection pump front plate equipment&tools (two-valve head) 05-170-8 timing mark transfer tool 05-190-2 cylinder head&valves essential tools engine oil dipstick tube driver (6010— (four-valve head) 05-170-10 6910 series tractor engines) 05-190-3 service equipment&tools (four-valve 05 head) 05-170-15 other material (four-valve head) 05-170-17 cylinder block, liners, pistons&rods essential tools 05-170-17 cylinder block, liners, pistons&rods service equipment&tools 05-170-22 cylinder block, liners, pistons&rods other materials 05-170-23 crankshaft, main bearings&flywheel essential tools 05-170-24 crankshaft, main bearings&flywheel service equipment&tools 05-170-29 crankshaft, main bearings&flywheel other materials 05-170-30 camshaft, balancer shafts&timing gear train essential tools 05-170-31 camshaft, balancer shafts&timing gear train service equipment and tools 05-170-35 camshaft, balancer shafts&timing gear train other materials 05-170-36 lubrication system essential tools 05-170-37 lubrication system service equipment and tools 05-170-41 lubrication system other materials 05-170-42 cooling system essential tools 05-170-43 cooling system service equipment and tools 05-170-44 cooling system other materials 05-170-45 air intake&exhaust system other materials 05-170-46 starting&charging system essential tools 05-170-47 ctm104 (11jul02) 05-1 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=1 contents 05 ctm104 (11jul02) 05-2 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=2 group 170 repair tools&other materials ouo1082,0000233 –19–30oct01–1/2 engine rebuild essential tools note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) servicegard is a trademark of deere & company 05 170 1 ouo1082,0000233 –19–30oct01–2/2 engine lifting sling jdg23 lift engine ctm104 (11jul02) 05-170-1 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=509 repair tools&other materials ouo1082,0000234 –19–30oct01–1/4 engine rebuild service equipment&tools note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) some tools may be available from a local supplier servicegard is a trademark of deere & company 05 170 2 ouo1082,0000234 –19–30oct01–2/4 engine repair stand d05223st used with d05226st special adapter&62835 engine adapter to mount engine ouo1082,0000234 –19–30oct01–3/4 special adapter d05226st used to mount 62835 engine adapter to d05223st engine repair stand ouo1082,0000234 –19–30oct01–4/4 engine adapter 62835 used with d05226st special adapter&d05223st engine repair stand to mount engine part of jt07268 engine repair stand adapter kit ctm104 (11jul02) 05-170-2 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=510 repair tools&other materials ouo1082,0000235 –19–30oct01–1/1 engine rebuild other materials number name use ty9370 (canadian) thread lock&sealer (medium apply to cap screws for engine lifting 242 (loctite?) strength) straps loctite is a trademark of loctite corp 05 170 3 dpsg,ouo1004,2707 –19–18jun02–1/15 cylinder head&valves essential tools (two-valve head) note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) servicegard is a trademark of deere & company dpsg,ouo1004,2707 –19–18jun02–2/15 rg6251 –un–22jul92 jde83 flywheel turning tool jde83 used to rotate flywheel on engines with 142-tooth flywheel ring gear&a 26 5 mm (1 04 in ) id flywheel housing guide bore diameter continued on next page ctm104 (11jul02) 05-170-3 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=511 repair tools&other materials dpsg,ouo1004,2707 –19–18jun02–3/15 rg7056 –un–05dec97 jde81-1 flywheel turning tool jde81-1 used to rotate flywheel on engines with 129-tooth flywheel ring gear&a 29 9 mm (1 18 in ) flywheel housing guide bore diameter jdg820 may be used if jde81-1 is not available jdg820 must be used for 6 8l engines in 7400&7600 tractors 05 170 4 dpsg,ouo1004,2707 –19–18jun02–4/15 rg5068 –un–05dec97 jde81-4 timing pin jde81-4 used to lock flywheel at no 1 tdc for injection pump timing do not use to lock engine when removing or installing damper retaining cap screws dpsg,ouo1004,2707 –19–18jun02–5/15 rg12031 –un–20dec01 jdg1571 timing pin jdg1571 used to lock flywheel at no 1 tdc for injection pump timing this timing pin must be used on engine applications using the tapered-nose crankshaft due to the higher torque specification for damper retaining cap screw ctm104 (11jul02) 05-170-4 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=512 continued on next page repair tools&other materials dpsg,ouo1004,2707 –19–18jun02–6/15 rg6246 –un–05dec97 d17526ci/d17527ci dial indicator d17526ci (english, in )/d17527ci (metric, mm) use with jdg451 height gauge/magnetic base to measure valve recess in cylinder head 05 170 5 dpsg,ouo1004,2707 –19–18jun02–7/15 rg7029 –un–05dec97 jdg451/kjd10123 height gauge jdg451/kjd10123 used with a dial indicator to measure valve recess in cylinder head also used to measure piston&liner height dpsg,ouo1004,2707 –19–18jun02–8/15 rg5070 –un–23aug88 jde138 valve spring compres*** jde138 used to compress valve springs when removing and installing valves dpsg,ouo1004,2707 –19–18jun02–9/15 rg5061 –un–05dec97 d01168aa spring compression tester d01168aa test valve spring compression ctm104 (11jul02) 05-170-5 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=513 continued on next page repair tools&other materials dpsg,ouo1004,2707 –19–18jun02–10/15 rg5084 –un–23aug88 jde39 nozzle bore cleaning tool jde39 clean injection nozzle bores in cylinder head 05 170 6 dpsg,ouo1004,2707 –19–18jun02–11/15 rg5064 –un–05dec97 jt05949 valve guide knurler kit jt05949 knurl valve guides dpsg,ouo1004,2707 –19–18jun02–12/15 rg5065 –un–05dec97 jdg676 valve seat driver jdg676 use with jdg675 adapter to install intake&exhaust valve seat inserts in cylinder head continued on next page ctm104 (11jul02) 05-170-6 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=514 repair tools&other materials dpsg,ouo1004,2707 –19–18jun02–13/15 rg5240 –un–05dec97 jdg675 valve seat insert installing adapter jdg675 use with jdg676 valve seat driver to install intake and exhaust valve seat inserts 05 170 7 dpsg,ouo1004,2707 –19–18jun02–14/15 rg5612 –un–12apr90 jdg678 valve stem seal installer jdg678 use to install valve stem seals dpsg,ouo1004,2707 –19–18jun02–15/15 rg5100 –un–05dec97 jdg680 tap jdg680 used to restore threaded holes in cylinder block for cylinder head cap screws ctm104 (11jul02) 05-170-7 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=515 repair tools&other materials dpsg,ouo1004,2708 –19–26apr00–1/9 cylinder head&valves service equipment and tools (two-valve head) note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) some tools may be available from a local supplier servicegard is a trademark of deere & company 05 170 8 dpsg,ouo1004,2708 –19–26apr00–2/9 crankshaft front/rear rotation adapter jdg966 rotate straight nose crankshaft from front&rear with flywheel removed dpsg,ouo1004,2708 –19–26apr00–3/9 valve inspection center check valves for out-of-round dpsg,ouo1004,2708 –19–26apr00–4/9 precision “bevelled edge” straightedge d05012st check cylinder head flatness dpsg,ouo1004,2708 –19–26apr00–5/9 plastic brush clean valve guides dpsg,ouo1004,2708 –19–26apr00–6/9 end brush d17024br remove carbon on valve seats dpsg,ouo1004,2708 –19–26apr00–7/9 heavy-duty seat grinder jt05893 grind valve seats ctm104 (11jul02) 05-170-8 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=516 continued on next page repair tools&other materials dpsg,ouo1004,2708 –19–26apr00–8/9 eccentrimeter measure valve seat runout dpsg,ouo1004,2708 –19–26apr00–9/9 torque angle gauge jt05993 used to torque-turn flanged-head cylinder head and connecting rod cap screws 05 170 9 ctm104 (11jul02) 05-170-9 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=517 repair tools&other materials dpsg,ouo1004,2707 –19–18jun02–1/15 cylinder head&valves essential tools (four-valve head) note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) servicegard is a trademark of deere & company 05 170 10 dpsg,ouo1004,2707 –19–18jun02–2/15 rg6251 –un–22jul92 jde83 flywheel turning tool jde83 used to rotate flywheel on engines with 142-tooth flywheel ring gear&a 26 5 mm (1 04 in ) id flywheel housing guide bore diameter dpsg,ouo1004,2707 –19–18jun02–3/15 rg7056 –un–05dec97 jde81-1 flywheel turning tool jde81-1 used to rotate flywheel on engines with 129-tooth flywheel ring gear&a 29 9 mm (1 18 in ) flywheel housing guide bore diameter jdg820 may be used if jde81-1 is not available jdg820 must be used for 6 8l engines in 7400&7600 tractors continued on next page ctm104 (11jul02) 05-170-10 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=518 repair tools&other materials dpsg,ouo1004,2707 –19–18jun02–4/15 rg5068 –un–05dec97 jde81-4 timing pin jde81-4 used to lock flywheel at no 1 tdc for injection pump timing do not use to lock engine when removing or installing damper retaining cap screws 05 170 11 dpsg,ouo1004,2707 –19–18jun02–5/15 rg12031 –un–20dec01 jdg1571 timing pin jdg1571 used to lock flywheel at no 1 tdc for injection pump timing this timing pin must be used on engine applications using the tapered-nose crankshaft due to the higher torque specification for damper retaining cap screw dpsg,ouo1004,2707 –19–18jun02–6/15 rg12410 –un–19jun02 jdg1652 fuel injector nozzle removal tool jdg1652 removes fuel injectors from four-valve head ctm104 (11jul02) 05-170-11 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=519 continued on next page repair tools&other materials dpsg,ouo1004,2707 –19–18jun02–7/15 rg6246 –un–05dec97 d17526ci/d17527ci dial indicator d17526ci (english, in )/d17527ci (metric, mm) use with jdg451/kjd10123 height gauge/magnetic base to measure valve recess in cylinder head 05 170 12 dpsg,ouo1004,2707 –19–18jun02–8/15 rg7029 –un–05dec97 jdg451/kjd10123 height gauge jdg451/kjd10123 used with a dial indicator to measure valve recess in cylinder head dpsg,ouo1004,2707 –19–18jun02–9/15 rg5070 –un–23aug88 jde138 valve spring compres*** jde138 used to compress valve springs when removing and installing valves dpsg,ouo1004,2707 –19–18jun02–10/15 rg5061 –un–05dec97 d01168aa spring compression tester d01168aa test valve spring compression ctm104 (11jul02) 05-170-12 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=520 continued on next page repair tools&other materials dpsg,ouo1004,2707 –19–18jun02–11/15 rg5064 –un–05dec97 jt05949 valve guide knurler kit jt05949 knurl valve guides 05 170 13 dpsg,ouo1004,2707 –19–18jun02–12/15 rg12408 –un–19jun02 jdg1653-1 valve seat driver jdg1653-1 use with jdg1653-2 adapter to install intake&exhaust valve seat inserts in cylinder head part of jdg1653 valve seat installation kit dpsg,ouo1004,2707 –19–18jun02–13/15 rg12409 –un–19jun02 jdg1653-2 valve seat insert installing adapter jdg1653-2 use with jdg1653-1 valve seat driver to install intake and exhaust valve seat inserts part of jdg1653 valve seat installation kit ctm104 (11jul02) 05-170-13 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=521 continued on next page repair tools&other materials dpsg,ouo1004,2707 –19–18jun02–14/15 rg12407 –un–19jun02 jdg1651 valve stem seal installer jdg1651 use to install valve stem seals 05 170 14 dpsg,ouo1004,2707 –19–18jun02–15/15 rg5100 –un–05dec97 jdg680 tap jdg680 used to restore threaded holes in cylinder block for cylinder head cap screws ctm104 (11jul02) 05-170-14 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=522 repair tools&other materials ouo1089,0000239 –19–18jun02–1/9 service equipment&tools (four-valve head) note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) some tools may be available from a local supplier servicegard is a trademark of deere & company 05 170 15 ouo1089,0000239 –19–18jun02–2/9 crankshaft front/rear rotation adapter jdg966 rotate straight nose crankshaft from front&rear with flywheel removed ouo1089,0000239 –19–18jun02–3/9 valve inspection center check valves for out-of-round ouo1089,0000239 –19–18jun02–4/9 precision “bevelled edge” straightedge d05012st check cylinder head flatness ouo1089,0000239 –19–18jun02–5/9 plastic brush clean fuel injection nozzle bores ouo1089,0000239 –19–18jun02–6/9 plastic brush clean glow plug bores ouo1089,0000239 –19–18jun02–7/9 plastic brush clean valve guides ctm104 (11jul02) 05-170-15 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=523 continued on next page repair tools&other materials ouo1089,0000239 –19–18jun02–8/9 end brush d17024br remove carbon on valve seats ouo1089,0000239 –19–18jun02–9/9 torque angle gauge jt05993 used to torque-turn flanged-head cylinder head and connecting rod cap screws 05 170 16 ctm104 (11jul02) 05-170-16 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=524 repair tools&other materials ouo1089,000023a –19–18jun02–1/1 other material (four-valve head) number name use t43514 (u s ) loctite 277 high strength, used to install end plugs on rocker threadlock (50 ml bottle) arm shaft ty9375 (u s ) loctite 592 (50 ml bottle) applied to outer surface of fuel injection nozzle sleeves ar44402 (u s ) lubricant coat valve stems&entire length of valve guide bores 05 170 17 dpsg,ouo1004,2711 –19–26apr00–1/14 cylinder block, liners, pistons&rods essential tools note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) servicegard is a trademark of deere & company dpsg,ouo1004,2711 –19–26apr00–2/14 rg6246 –un–05dec97 d17526ci/d17527ci dial indicator d17526ci (english, in )/d17527ci (metric, mm) use with jdg451, kjd10123/magnetic base to measure valve recess in cylinder head&piston and liner height continued on next page ctm104 (11jul02) 05-170-17 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=525 repair tools&other materials dpsg,ouo1004,2711 –19–26apr00–3/14 rg7029 –un–05dec97 jdg451/kjd10123 height gauge jdg451/kjd10123 used with a dial indicator to measure valve recess in cylinder head also used to measure piston&liner height 05 170 18 dpsg,ouo1004,2711 –19–26apr00–4/14 rg5019 –un–05dec97 d01062aa/d01073aa/kcd10001 cylinder liner puller d01062aa, d01073aa or kcd10001 used to remove&install cylinder liners dpsg,ouo1004,2711 –19–26apr00–5/14 rg9441 –un–10jul98 jdg1145 cylinder liner puller jdg1145 used to remove&install cylinder liners continued on next page ctm104 (11jul02) 05-170-18 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=526 repair tools&other materials dpsg,ouo1004,2711 –19–26apr00–6/14 rg7406 –un–21may98 jde85/jde135/kjd10140 piston ring expander jde85, jde135, kjd10140 remove&install piston rings 05 170 19 dpsg,ouo1004,2711 –19–26apr00–7/14 rg5076 –un–23aug88 jde62/jdg957 piston ring groove wear gauge jde62 check wear of keystone ring groove on pistons with tapered rods piston ring groove wear gauge jdg957 check wear of keystone ring groove on pistons with straight rods dpsg,ouo1004,2711 –19–26apr00–8/14 rg5074 –un–07nov97 d17004br flexible cylinder hone d17004br hone cylinder liners continued on next page ctm104 (11jul02) 05-170-19 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=527 repair tools&other materials dpsg,ouo1004,2711 –19–26apr00–9/14 rg5107 –un–23aug88 jd286 (jd-286) piston pin bushing remover&installer jd286 (jd-286) remove&install large 41 mm (1 6 in ) piston pin bushings piston pin bushing remover&installer jde88 remove&install small 35 mm (1 3 in ) piston pin bushings 05 170 20 dpsg,ouo1004,2711 –19–26apr00–10/14 rg9126 –un–22apr98 jdg953 connecting rod bushing service set jdg953 replace pin bushing in connecting rods with tapered pin-end dpsg,ouo1004,2711 –19–26apr00–11/14 rg11804 –un–25oct01 jdg782a oil gallery plug tool jdg782a used to remove&install oil gallery plug continued on next page ctm104 (11jul02) 05-170-20 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=528 repair tools&other materials dpsg,ouo1004,2711 –19–26apr00–12/14 rg5100 –un–05dec97 jdg680 tap jdg680 used to restore threaded holes in cylinder block for cylinder head cap screws 05 170 21 dpsg,ouo1004,2711 –19–26apr00–13/14 rg5075 –un–07nov97 d17015br o-ring groove cleaning brush d17015br clean cylinder liner o-ring groove in block dpsg,ouo1004,2711 –19–26apr00–14/14 rg5031 –un–05dec97 jde84 piston ring compres*** jde84 compress rings while installing pistons ctm104 (11jul02) 05-170-21 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=529 repair tools&other materials dpsg,ouo1004,2713 –19–26apr00–1/4 cylinder block, liners, pistons&rods service equipment&tools note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) some tools may be available from a local supplier servicegard is a trademark of deere & company 05 170 22 dpsg,ouo1004,2713 –19–26apr00–2/4 piston ring groove cleaning tool n/a clean piston ring grooves dpsg,ouo1004,2713 –19–26apr00–3/4 precision “bevelled edge” straightedge d05012st check cylinder head flatness dpsg,ouo1004,2713 –19–26apr00–4/4 torque angle gauge jt05993 used to torque-turn flanged-head cylinder head and connecting rod cap screws ctm104 (11jul02) 05-170-22 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=530 repair tools&other materials 05 170 23 dpsg,ouo1004,2712 –19–26apr00–1/1 cylinder block, liners, pistons&rods other materials number name use n/a (u s ) plastigage? determine connecting rod bearing-to-journal oil clearance t43512 (u s ) thread lock&sealer (medium apply to cylinder block oil gallery ty9473 (canadian) strength) plugs 242 (loctite?) ty9375 (u s ) pipe sealant apply to cylinder block coolant ty9480 (canadian) gallery plugs 592 (loctite?) t43514 (u s ) plastic gasket apply to steel caps/soft plugs in ty9475 (canadian) cylinder block 277 (loctite?) ar54749 (u s ) soap lubricant apply to cylinder liner o-rings and packing plastigage is a registered trademark of dana corp loctite is a registered trademark of loctite corp ctm104 (11jul02) 05-170-23 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=531 repair tools&other materials dpsg,ouo1004,2715 –19–26apr00–1/14 crankshaft, main bearings&flywheel essential tools note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) servicegard is a trademark of deere & company 05 170 24 dpsg,ouo1004,2715 –19–26apr00–2/14 rg6246 –un–05dec97 d17526ci/d17527ci dial indicator d17526ci (english, in )/d17527ci (metric, mm) used with magnetic base to measure radial runout (concentricity)&wobble on vibration damper dpsg,ouo1004,2715 –19–26apr00–3/14 rg7056 –un–05dec97 jde81-1 flywheel turning tool jde81-1 used to rotate flywheel on engines with 129-tooth flywheel ring gear&a 29 9 mm (1 18 in ) flywheel housing guide bore diameter jdg820 may be used if jde81-1 is not available jdg820 must be used for 6 8l engines in 7400&7600 tractors continued on next page ctm104 (11jul02) 05-170-24 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=532 repair tools&other materials dpsg,ouo1004,2715 –19–26apr00–4/14 rg6251 –un–22jul92 jde83 flywheel turning tool jde83 used to rotate flywheel on engines with 142-tooth flywheel ring gear&a 26 5 mm (1 04 in ) flywheel housing guide bore diameter 05 170 25 dpsg,ouo1004,2715 –19–26apr00–5/14 rg5109 –un–23aug88 jdg22 seal remover jdg22 remove crankshaft front oil seal with timing gear cover installed also used to remove crankshaft rear oil seal without removing flywheel housing dpsg,ouo1004,2715 –19–26apr00–6/14 rg6214 –un–05dec97 jdg719 seal puller adapter jdg719 used with standard metal screw, jde38-2 shank, and jde38-3 slide handle to remove front crankshaft oil seal with timing gear cover installed also used to remove rear crankshaft oil seal with seal housing installed continued on next page ctm104 (11jul02) 05-170-25 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=533 repair tools&other materials dpsg,ouo1004,2715 –19–26apr00–7/14 rg12031 –un–20dec01 jdg1571 timing pin jdg1571 used to lock flywheel at no 1 tdc for injection pump timing this timing pin must be used on engine applications using the tapered-nose crankshaft due to the higher torque specification for damper retaining cap screw 05 170 26 dpsg,ouo1004,2715 –19–26apr00–8/14 rg5068 –un–05dec97 timing pin timing pin jde81-4 used to lock engine/flywheel dpsg,ouo1004,2715 –19–26apr00–9/14 rg9124 –un–22apr98 jdg992-1 front wear sleeve puller jdg992-1 used with jdg992-2 front wear sleeve puller to remove front wear sleeve with timing gear cover installed ctm104 (11jul02) 05-170-26 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=534 continued on next page repair tools&other materials dpsg,ouo1004,2715 –19–26apr00–10/14 rg9125 –un–19may98 jdg992-2 front wear sleeve puller jdg992-2 used with jdg992-1 to remove front wear sleeve with timing gear cover installed 05 170 27 dpsg,ouo1004,2715 –19–26apr00–11/14 rg5631 –un–12apr90 jdg698a seal&wear sleeve remover jdg698a remove unitized crankshaft rear oil seal&wear sleeve dpsg,ouo1004,2715 –19–26apr00–12/14 cd30241 –un–08mar95 jdg645e rear crankshaft oil seal/wear sleeve puller jdg645e remove rear oil seal/wear sleeve from crankshaft flange ctm104 (11jul02) 05-170-27 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=535 continued on next page repair tools&other materials dpsg,ouo1004,2715 –19–26apr00–13/14 rg9122 –un–22apr98 jt30040b/kcd10002a rear oil seal/wear sleeve installer set jt30040b or kcd10002a install crankshaft rear oil seal/wear sleeve assembly 05 170 28 dpsg,ouo1004,2715 –19–26apr00–14/14 rg12034 –un–11jan02 jdg954b crankshaft gear&front oil seal installer jdg954b used to install the crankshaft gear either prior to,/after installing crankshaft into engine also used to install front oil seal with timing gear cover installed on engine and used to install timing wheel on crankshaft ctm104 (11jul02) 05-170-28 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=536 repair tools&other materials dpsg,ouo1004,2716 –19–26apr00–1/4 crankshaft, main bearings&flywheel service equipment&tools note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) some tools may be available from a local supplier servicegard is a trademark of deere & company 05 170 29 dpsg,ouo1004,2716 –19–26apr00–2/4 bushing, bearing&seal driver set d01045aa install pilot bearing in flywheel&nb, sp; dpsg,ouo1004,2716 –19–26apr00–3/4 pulling attachment d01218aa use with d01200aa push puller to remove crankshaft gear from crankshaft dpsg,ouo1004,2716 –19–26apr00–4/4 push puller d01200aa use with d01218aa to remove crankshaft gear from crankshaft ctm104 (11jul02) 05-170-29 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=537 repair tools&other materials 05 170 30 dpsg,ouo1004,2717 –19–24may02–1/1 crankshaft, main bearings&flywheel other materials number name use ty16285 (u s ) cure primer used to clean nose of crankshaft for cxty16285 (canadian) damper installation 7649 (loctite?) ty15969 (u s ) retaining compound (maximum used to retain vibration damper to ty9479 (canadian) strength) crankshaft 680 (loctite?) brake kleen/ignition cleaner remove sealant from crankshaft flange ty15969 (u s ) retaining compound (maximum apply to crankshaft front wear ty9479 (canadian) strength) sleeve 680 (loctite?) t43513 (u s ) thread lock&sealer (high apply to threaded studs of flywheel ty9474 (canadian) strength) (option code 1557) 271 (loctite?) plastigage? check main bearing-to-crankshaft journal oil clearance ty6304 (u s ) flexible form-in-place gasket apply to cylinder block front plate, ty9484 (canadian) crankshaft flywheel hub (1568 loctite? 515 (loctite?) flywheel option code), rear face of cylinder block prior to installing flywheel housing&merit tractor flywheel housing m20 cap screw surface t43514 (u s ) plastic gasket apply to torque converter access ty9475 (canadian) hole plug 277 (loctite?) loctite is a trademark of loctite corp loctite is a registered trademark of loctite corp plastigage is a registered trademark of dana corp ctm104 (11jul02) 05-170-30 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=538 repair tools&other materials dpsg,ouo1004,2723 –19–26apr00–1/12 camshaft, balancer shafts&timing gear train essential tools note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) servicegard is a trademark of deere & company 05 170 31 dpsg,ouo1004,2723 –19–26apr00–2/12 rg7056 –un–05dec97 jde81-1 flywheel turning tool jde81-1 used to rotate flywheel on engines with 129-tooth flywheel ring gear&a 29 9 mm (1 18 in ) flywheel housing guide bore diameter jdg820 may be used if jde81-1 is not available jdg820 must be used for 6 8l engines in 7400&7600 tractors dpsg,ouo1004,2723 –19–26apr00–3/12 rg6251 –un–22jul92 jde83 flywheel turning tool jde83 used to rotate flywheel on engines with 142-tooth flywheel ring gears&a 26 5 mm (1 04 in ) id flywheel housing guide bore diameter continued on next page ctm104 (11jul02) 05-170-31 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=539 repair tools&other materials dpsg,ouo1004,2723 –19–26apr00–4/12 rg5068 –un–05dec97 jde81-4 timing pin jde81-4 used to lock flywheel at no 1 tdc for injection pump timing do not use to lock engine when removing or installing damper retaining cap screws 05 170 32 dpsg,ouo1004,2723 –19–26apr00–5/12 rg12031 –un–20dec01 jdg1571 timing pin jdg1571 used to lock flywheel at no 1 tdc for injection pump timing this timing pin must be used on engine applications using the tapered-nose crankshaft due to the higher torque specification for damper retaining cap screw dpsg,ouo1004,2723 –19–26apr00–6/12 rg9121 –un–22apr98 jdg739b camshaft bushing service set jdg739b used to remove&install front camshaft bushing ctm104 (11jul02) 05-170-32 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=540 continued on next page repair tools&other materials dpsg,ouo1004,2723 –19–26apr00–7/12 rg5120 –un–05dec97 jd249 (jd-249) balancer shaft bushing driver jd249 (jd-249) use with jdg963 balancer shaft bushing adapter to replace balancer shaft bushings 05 170 33 dpsg,ouo1004,2723 –19–26apr00–8/12 rg7940 –un–15jan98 jdg963 balancer shaft bushing adapter jdg963 use with jd249 (jd-249) balancer shaft bushing driver to remove&install balancer shaft bushings dpsg,ouo1004,2723 –19–26apr00–9/12 rg10566 –un–28jan00 jd252 (jd-252) idler gear bushing driver jd252 (jd-252) use with jdg537 handle to remove&install idler gear bushings continued on next page ctm104 (11jul02) 05-170-33 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=541 repair tools&other materials dpsg,ouo1004,2723 –19–26apr00–10/12 rg10567 –un–28jan00 jdg537 handle jdg537 (otc815) use with jd252 (jd-252) idler gear bushing driver to remove&install idler gear bushings 05 170 34 dpsg,ouo1004,2723 –19–26apr00–11/12 rg7443 –un–23nov97 jd254a (jd-254a) gear timing tool jd254a (jd-254a) time camshaft gear, injection pump gear&balancer shafts dpsg,ouo1004,2723 –19–26apr00–12/12 rg7939 –un–05jan98 jdg791a idler gear installer pilot jdg791a guide upper idler gear onto idler shaft ctm104 (11jul02) 05-170-34 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=542 repair tools&other materials dpsg,ouo1004,2724 –19–26apr00–1/5 camshaft, balancer shafts&timing gear train service equipment&tools note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) some tools may be available from a local supplier servicegard is a trademark of deere & company 05 170 35 dpsg,ouo1004,2724 –19–26apr00–2/5 magnetic follower holder kit d15001nu hold camshaft followers when removing&installing camshaft dpsg,ouo1004,2724 –19–26apr00–3/5 balancer shaft holding tool jd247 (jd-247) hold balancer shaft while pressing gear on shaft dpsg,ouo1004,2724 –19–26apr00–4/5 torx? driver set remove&install engine front plate mounting hardware torx is a registered trademark of camcar/textron dpsg,ouo1004,2724 –19–26apr00–5/5 master driver set d01045aa use discs with jdg537 handle to remove&install idler gear bushings install pilot bearing in flywheel ctm104 (11jul02) 05-170-35 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=543 repair tools&other materials 05 170 36 dpsg,ouo1004,2725 –19–26apr00–1/1 camshaft, balancer shafts&timing gear train other materials number name use ty6333 (u s ) high-temperature grease coat camshaft followers, camshaft lobes, journals&bushings during installation coat idler gear, bushing, and shaft during installation ty6304 (u s ) flexible form-in-place gasket apply to cylinder block front plate ty9484 (canadian) 515 (loctite?) t43512 (u s ) thread lock&sealer (medium apply to injection pump cover cap ty9473 (canadian) strength) screws 242 (loctite?) t43513 (u s ) thread lock&sealer (high apply to four timing gear cover studs ty9474 (canadian) strength) used on oem engine applications 271 (loctite?) with auxiliary driven hydraulic pump ty9375 (u s ) pipe sealant apply to one timing gear cover cap ty9480 (canadian) screw 592 (loctite?) loctite is a registered trademark of loctite corp ctm104 (11jul02) 05-170-36 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=544 repair tools&other materials dpsg,ouo1004,2727 –19–26apr00–1/11 lubrication system essential tools note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) servicegard is a trademark of deere & company 05 170 37 dpsg,ouo1004,2727 –19–26apr00–2/11 rg5061 –un–05dec97 d01168aa spring compression tester d01168aa test oil bypass valve&oil pressure regulating valve spring compression dpsg,ouo1004,2727 –19–26apr00–3/11 rg9118 –un–17apr98 jd248a (jd-248a) oil pressure relief valve bushing driver jd248a (jd-248a) use with jdg536 handle to install oil pressure relief valve bushing dpsg,ouo1004,2727 –19–26apr00–4/11 rg9117 –un–17apr98 jdg536 handle jdg536 (oct813) use with jd248a (jd-248a) bushing driver to install oil pressure relief valve bushing continued on next page ctm104 (11jul02) 05-170-37 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=545 repair tools&other materials dpsg,ouo1004,2727 –19–26apr00–5/11 rg11788 –un–25sep01 jd1517 pressure regulating valve installer&remover tool set jdg1517 used to remove oil pressure regulating valve from the engine block 05 170 38 dpsg,ouo1004,2727 –19–26apr00–6/11 rg7982 –un–15jan98 jdg965 dipstick driver jdg965 install dipstick tube in block dpsg,ouo1004,2727 –19–26apr00–7/11 rg9114 –un–07apr98 jdg1146 dipstick fitting installer jdg1146 install dipstick tube fitting in block continued on next page ctm104 (11jul02) 05-170-38 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=546 repair tools&other materials dpsg,ouo1004,2727 –19–26apr00–8/11 rg7056 –un–05dec97 jde81-1 flywheel turning tool jde81-1 used to rotate flywheel on engines with 129-tooth flywheel ring gear&a 29 9 mm (1 18 in ) flywheel housing guide bore diameter jdg820 may be used if jde81-1 is not available jdg820 must be used for 6 8l engines in 7400&7600 tractors 05 170 39 dpsg,ouo1004,2727 –19–26apr00–9/11 rg6251 –un–22jul92 jde83 flywheel turning tool jde83 used to rotate flywheel on engines with 142-tooth flywheel ring gear&a 26 5 mm (1 04 in ) flywheel housing guide bore diameter dpsg,ouo1004,2727 –19–26apr00–10/11 rg5068 –un–05dec97 jde81-4 timing pin jde81-4 used to lock flywheel at no 1 tdc for injection pump timing do not use to lock engine when removing or installing damper retaining cap screws continued on next page ctm104 (11jul02) 05-170-39 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=547 repair tools&other materials dpsg,ouo1004,2727 –19–26apr00–11/11 rg12031 –un–20dec01 jdg1571 timing pin jdg1571 used to lock flywheel at no 1 tdc for injection pump timing this timing pin must be used on engine applications using the tapered-nose crankshaft due to the higher torque specification for damper retaining cap screw 05 170 40 ctm104 (11jul02) 05-170-40 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=548 repair tools&other materials dpsg,ouo1004,2728 –19–26apr00–1/5 lubrication system service equipment and tools note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) some tools may be available from a local supplier servicegard is a trademark of deere & company 05 170 41 dpsg,ouo1004,2728 –19–26apr00–2/5 blind-hole puller set d01061aa remove oil filter bypass valve (extended-life filter), oil pressure regulating valve seat&dipstick tube from block dpsg,ouo1004,2728 –19–26apr00–3/5 collet (5/16 in ) jt01724 (33856) used with jt01720 actuator pin&1156 slide hammer to remove dipstick tube from cylinder block dpsg,ouo1004,2728 –19–26apr00–4/5 actuator pin jt01720 (28250) used with jt01724 collet&1156 slide hammer to remove dipstick tube from cylinder block dpsg,ouo1004,2728 –19–26apr00–5/5 slide hammer 1156 (formerly d01299aa) used with jdg1517 pressure regulating valve installer and remover tool set to remove oil pressure regulating valve used with jt01724 collet&jt01720 actuator pin to remove dipstick tube from cylinder block ctm104 (11jul02) 05-170-41 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=549 repair tools&other materials 05 170 42 dpsg,ouo1004,2729 –19–26apr00–1/1 lubrication system other materials number name use t43512 (u s ) thread lock&sealer (medium apply to oil cooler-to-housing cap ty9473 (canadian) strength) screws, oil fill tube cap screws, and 242 (loctite?) end of dipstick tube t43513 (u s ) thread lock&sealer (high apply to dipstick tube with fitting ty9474 (canadian) strength) 271 (loctite?) ty6304 (u s ) flexible form-in-place gasket apply to oil pan rail ty9484 (canadian) 515 (loctite?) ty9375 (u s ) pipe sealant apply to oil pan elbow drain fitting ty9480 (canadian) 592 (loctite?) loctite is a registered trademark of loctite corp ctm104 (11jul02) 05-170-42 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=550 repair tools&other materials dpsg,ouo1004,2731 –19–26apr00–1/4 cooling system essential tools note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) servicegard is a trademark of deere & company 05 170 43 dpsg,ouo1004,2731 –19–26apr00–2/4 rg7950 –un–05jan98 jdg956 coolant pump bearing installer jdg956 install coolant pump bearing dpsg,ouo1004,2731 –19–26apr00–3/4 jdg529 –un–10may95 jdg1341 belt tension gauge jdg1341 used to check belt tension on 8-rib poly-vee belt dpsg,ouo1004,2731 –19–26apr00–4/4 rg11769 –un–28aug01 jdg1520 belt tensioning tool jdg1520 used to adjust belt tension on engines with manual belt tensioner ctm104 (11jul02) 05-170-43 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=551 repair tools&other materials dpsg,ouo1004,2732 –19–26apr00–1/2 cooling system service equipment and tools note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) some tools may be available from a local supplier servicegard is a trademark of deere & company 05 170 44 dpsg,ouo1004,2732 –19–26apr00–2/2 bushing, bearing&seal driver set d01045aa remove inner seal in coolant pump housing ctm104 (11jul02) 05-170-44 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=552 repair tools&other materials dpsg,ouo1004,2733 –19–26apr00–1/1 cooling system other materials number name use pt507 (u s ) multi-purpose grease thermostat housing o-rings n/a (u s ) rtv silicone sealant seal coolant pump insert to timing 5699 (loctite?) gear cover jdt308 (u s ) soap lubricant apply to coolant heater o-ring 05 170 45 loctite is a trademark of loctite corp ctm104 (11jul02) 05-170-45 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=553 repair tools&other materials dpsg,ouo1004,2735 –19–26apr00–1/1 air intake&exhaust system other materials number name use pt569 (u s ) never-seez? exhaust manifold-to-cylinder head cap screws ty9375 (u s ) pipe sealant air heater threads ty9480 (canadian) 592 (loctite?) 05 170 46 never-seez is a registered trademark of emhart chemical group loctite is a registered trademark of loctite corp ctm104 (11jul02) 05-170-46 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=554 repair tools&other materials dpsg,ouo1004,1141 –19–18nov99–1/2 starting&charging system essential tools note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) servicegard is a trademark of deere & company 05 170 47 dpsg,ouo1004,1141 –19–18nov99–2/2 rg9116 –un–19may98 kjd10213 starter motor removal tool kjd10213 used to remove starter motor on when access is limited ctm104 (11jul02) 05-170-47 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=555 repair tools&other materials 05 170 48 ctm104 (11jul02) 05-170-48 powertech? 4 5 l & 6 8 l diesel engi, nes 071102 pn=556 group 180 diagnostic service tools dpsg,ouo1004,2738 –19–26apr00–1/6 diagnostic essential tools note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) servicegard is a trademark of deere & company 05 180 1 dpsg,ouo1004,2738 –19–26apr00–2/6 rg5161 –un–23aug88 jt01674 compression test set jt01674 (formerly d14546ba or fkm10021) used to check cylinder compression pressure use adapter&gauge/hose assembly from set dpsg,ouo1004,2738 –19–26apr00–3/6 rg11804 –un–25oct01 jdg782a oil gallery plug tool jdg782a used to remove&install oil gallery plug continued on next page ctm104 (11jul02) 05-180-1 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=557 diagnostic service tools dpsg,ouo1004,2738 –19–26apr00–4/6 rg5162 –un–23aug88 jt05470 universal pressure test kit jt05470 (d15027nu or fkm10002) used to check engine oil pressure 05 180 2 dpsg,ouo1004,2738 –19–26apr00–5/6 r26406n –un–29nov88 d05104st cooling system pressure pump d05104st used to pressure test radiator cap&cooling system dpsg,ouo1004,2738 –19–26apr00–6/6 rg5163 –un–23aug88 jde147 manifold pressure tester jde147/fkm10002 used to test intake manifold pressure on turbocharged engines ctm104 (11jul02) 05-180-2 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=558 diagnostic service tools dpsg,ouo1004,2739 –19–26apr00–1/4 diagnostic service equipment&tools note: order tools according to information given in the u s servicegard? catalog/from the european microfiche tool catalog (mtc) some tools may be available from a local supplier 认准指定代理商,和田和田县供应CAT卡特330凸轮轴曲轴查询中心,达州宣汉县强鹿柴油燃油泵解决方案?,河北保定雄县福格勒摊铺机1800发动机配件谁知道价格?,林芝朗县珀金斯发动机1104D配件联系方式?,

泰安泰山帕金斯三缸柴油机供应服务商?,内蒙古自治锡林郭勒正蓝旗帕金斯发动机油泵电磁阀价格透明,德宏芒英国威尔信P65E1发电机配件专卖店,宝鸡金台103-8008卡特滤清器供应服务商?,

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska