配件详情

麦克福斯约翰迪尔发动机零配件

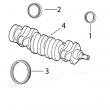

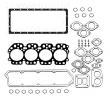

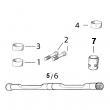

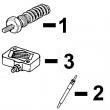

约翰迪尔 4045 4.5T/H 活塞(米) RE527039 排放 2 & 3

|

|

|

发动机和设备型号

|

孔径: 4.19 in 106.5 mm

销径 Ø: 1.6250 in (+/- .0002) = 41mm

发动机型号代码:

4045HE051

4045HL282

4045HL287

4045HL287

4045HT054

4045HT064

4045HT065

4045HT067

4045HT074

4045HT075

4045HDW53

4045HT067

4045HDW54

4045HE050

4045HL280

4045HL281

4045HL282

4045HL283

4045HL284

4045HL287

4045HL288

4045HP052

4045HT054

4045HT056

4045HT059

4045HT061

4045HT064

4045HT065

4045HT072

4045HT086

4045HT087

4045HT281

|

|

|

供应美国约翰.迪尔(强鹿)JOHNDEERE纯正配件。P550758、P550020、P550595、P558329、P550351、P551421、P551423、P556745、P551428、P551422、P551435、P551434、P550192、P550397、P551352、P181054、P77868、P777869、P550667、P550779

强鹿JOHN DEERE柴油机配件、发动机配件、发电机组:

P551345、P608667、P607557、P611856、P611857、P124866、P124867、P551130、P777638、P181099、P772579、P827653、P771548、P771548、P827653、P772579、P772580、P829333、P13194、P550388、C125017、C125004、P772579、C085001、C085002