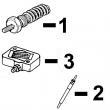

配件详情

麦克福斯约翰迪尔发动机零配件

|

|

|

约翰迪尔 4045 4.5T/H 活塞(米) RE55512/RE505102

|

|

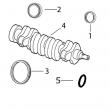

||||||||||||||||||||||||||||

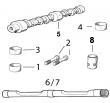

(1)使用机器拆分连杆使用TR114083,并使用<带断裂分离式连杆的断路器。

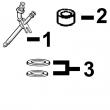

(2)使用Oil Pan code 1901,1902&amp; 1903年,钢制油锅。

(3)使用Oil Pan code 1904&amp; 1905年,为铝油盘。

(4)用法兰头帽螺钉更换所有R78558带帽螺钉TR85363。

(5)(m)R135439,R132324,R134213。

(6)线路连接都是线程化的。

(7)1件组合式密封和护套;替换TRE59810,RE538097。

(8)在曲轴加工过程中必须保持正确的轴承轴颈半径,以确保正确的操作。

(9)检查应用程序是否正确使用。

(10)与Stanadyne DE10注射泵一起使用。

(11)锥形鼻子。

(12)直鼻。

(13)线路连接是一个&nbsp;软管倒钩&amp;一个线程。

(14)线路连接是两个软管倒钩。

(15)机器分体式和断裂式分体式连杆均可用于同一台发动机,但每个连杆必须使用正确的连杆螺栓。

强鹿JOHN DEERE柴油机配件、发动机配件、发电机组:

4039DFM,6068SM50 ,RE522528、RE519774、RE532628、RE518176、RE507980、RE518503、RE522515、RE504836、RE509031、RE509032、RE59754、RE507284、RE59754、RE519626、RE518977、RE508202、RE58935、T19044、RE62418、RE62419、RE521248、RE520842、C085004、AR95758、LVA10419、AH128449、RE509672、RE196945、RE191915、RE522688、RE522687、RE519774、RE532628