配件详情

麦克福斯约翰迪尔发动机零配件

约翰迪尔 6068T/H 6.8T/H 活塞(米)RE515037 排放 2 & 3

|

|

||||||||||||||||||||||||||||

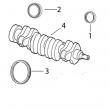

(1)1件组合式密封和穿套; 替换TRE59810,RE538097。

(2)曲轴加工过程中必须保持适当的轴承轴颈半径,以保证正确的操作。

(3)曲轴(m)R116076,直鼻。

(4)曲轴(m)R503470,锥形鼻。

(5)检查应用程序是否正确使用。

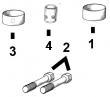

(6)线路连接都是线程化的。

(7)线路连接是一个软管倒钩& 一个线程。

(8)线路连接是两个软管倒钩。

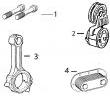

(9)机器分体式和断裂式分体式连杆均可用于同一台发动机,但每个连杆必须使用正确的连杆螺栓。

强鹿JOHNDEERE 高压油泵型号:

RE506965、RE53785、RE506879、RE506879、RE64241、RE503049、RE505052、SE501237、RE518089、RE506883、RE503051、RE508613、RE502711、SE501237、RE518164、SE501234、RE518167、RE501317、RE506085、RE506084、RE51866、SE501235、SE501234、RE505475、RE539769、RE518088、RE518166、RE503049

1a2 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) for english readers information&guideline of this parts catalog be sure to read the engine information (section 009)&parts catalog guidelines for a proper use of the catalog&an easy ordering of the parts (section 010) pour les lecteurs francais information et guide d’utilisation du catalogue veuillez vous referer aux informations moteur (section 009) et au guide d’utilisation du catalogue pour une lecture facile necessaire a la commande des pieces de rechange (section 011) fuer deutsche leser hinweis und gebrauchsanweisung des ersatzteilkatalogs fuer problemlose ersatzteilbestellung wird gruendlisches durchlesen der motorinformation (index 009) und der gerbrauchsanweisung (index 012) empfohlen- per il lettore italiano informazioni e guida per l’uso del catalogo per una lettura facile e necessario per ordinare le pezzi di ricambio, vogliate riferirvi alle informazioni motori (seccion 009) e alle guida per l’uso del catalogo (sezione 013)- para lectores en espanol informacion y a la guia de utilizacion del catalogo siga a las informaciones de motor (seccion 009) y a la guia de uso del catalogo para leer facilmente y pedir las piezas de recambio (seccion 014)- foer svenska laesare information och raad foer anvaendning av katalogen laes motor informationen (sektion 009) och bruksanvisning foer baesta anvaendning av katalogen och enkel baestaelning av delar (sektion 015)- genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 9-1 pn=1 1a3 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) codes used in "remarks" column codes utilises dans la colonne "remarques" kode-zeichen in der spalte "bemerkungen" lvp454 -un-23sep94 9-2 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=2 1a4 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) codici usati nella collona "note" codificacion en la columna "notas" kodats som anvands pa kolumn "anmarkningar" lvp455 -un-23sep94 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 9-3 pn=3 1a5 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) engine information informations moteur motorinformation informazioni motori informacion de motor motor informationen cd39701a -un-20feb96 9-4 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=4 1a6 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) engine information informations moteur motorinformation informazioni motori informacion de motor motor informationen cd37245 -un-09feb96 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 9-5 pn=5 1a7 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) engine information informations moteur motorinformation informazioni motori informacion de motor motor informationen cd37246 -un-13feb96 9-6 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=6 1a8 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) engine grouping information engines in this catalog are manufactured in saran only- these engines could be naturally-aspirated diesel/turbocharger diesel to assist your john deere parts depot in giving you prompt&efficient service, refer to the engine serial number plate for proper engine type identification- engine serial number plate cd37200 -un-01jan94 1- designates engine manufacturer cd - saran 2- designates number of cylinders 3/4/6 3- designates total displacement (in liter) 029 (2-9 liter)(bore 4-19" x stroke 4-33") 039 (3-9 liter)(bore 4-19" x stroke 4-33") 045 (4-5 liter)(bore 4-19" x stroke 5-00") 059 (5-9 liter)(bore 4-19" x stroke 4-33") 068 (6-8 liter)(bore 4-19" x stroke 5-00") 4- designates the type of aspiration d - naturally-aspirated diesel t - turbocharged diesel 5- designates engine serial number 123456 (six digits) 6- designates engine user f (oem) 7- designates the version 123 (three digits, not used) genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 10-1 pn=7 1a9 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) engine option code label cd37240 -un-17feb95 engine option codes in addition to the serial number plate, oem engines have an engine option code label affixed to the rocker arm cover-these codes indicates which of the engine options were installed on your engine at the factory-when in need of parts/service, furnish your authorized servicing dealer or engine distributor with these numbers- the first two digits of each code identify a specific group, such as an alternator-the two last digits of each code identify one specific option provided on your engine, such as a 12 volts, 55 amperes alternator- if an engine is ordered without a particular component, the last two digits of that functional group option code will be 9- 10-2 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=8 1a10 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) option codes description description des codes options zubehoerkode beschreibung cd37241 -un-17feb95 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 10-3 pn=9 1a11 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) option codes description description des codes options zubehoerkode beschreibung cd37242 -un-17feb95 10-4 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=10 1a12 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) serial number listing information serial number information is listed to show on which machines each part can be used- for example: - the part can be used on all machines- -000000 the part can be used on all machines up to&including the serial number- 000000- the part can be used on all machines beginning with the serial number listed- 000000-000000 the part can be used on all machines between&including the serial numbers listed- when xxxxxx’s are listed in place of serial numbers, a serial number change was made but the exact serial number was not available when the catalog was produced- box-enclosed illustrations a key number, shown in the parts list, is assigned to a box enclosing all parts sold as a service assembly-a box not keyed includes non-current parts- change indicator line (microfiche parts catalogs only) changes affecting the ordering of parts are identified by vertical lines marked in the left-hand margin of revised parts listing images- a line is also at the left-hand edge of the same part number in the numerical index to show the location of revised information- genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 10-5 pn=11 1a13 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) section index engine information - 09 operating instructions - 10 engine (cd3029df) - 20 engine (cd4039df/cd4039tf) - 21 engine (cd4045tf) - 22 engine (cd6059tf/cd6068tf) - 23 intake/exhaust 25 fuel system - 30 injection system - 35 starter - 40 alternator - 50 air cleaner - 60 belt/fan/radiator - 70 acces***y parts - 80 instrument panel - 90 numerical index - 95 10-6 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=12 1a14 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) informations concernant les moteurs les moteurs figurant dans ce catalogue sont fabriques uniquement a saran- ce sont des moteurs diesel avec ou sans turbocompresseur- le numero de serie figurant sur la plaquette signaletique permet une identification correcte du type de moteur- le depot pieces de rechange peut ainsi fournir un service rapide et efficace- plaquette signaletique du moteur cd37200 -un-01jan94 1- usine de fabrication cd - saran 2- nombre de cylindres 3 ou 4 ou 6 3- cylindree totale en litre 029 (2-9 l)(alesage 106-5mm x course 110mm) 039 (3-9 l)(alesage 106-5mm x course 110mm) 045 (4-5 l)(alesage 106-5mm x course 127mm) 059 (5-9 l)(alesage 106-5mm x course 110mm) 068 (6-8 l)(alesage 106-5mm x course 127mm) 4- mode d’alimentation d - moteur diesel sans turbocompresseur t - moteur diesel avec turbocompresseur 5- numero de serie du moteur 123456 (six chiffres) 6- utilisateur f (oem) 7- type de moteur 123 (trois chiffres, non utilises) genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 11-1 pn=13 1a15 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) etiquette de codes accessoires du moteur cd37240 -un-17feb95 codes accessoires du moteur en plus de la plaque du numero de serie du moteur, les moteurs oem ont une etiquette de codes accessoires du moteur situee sur le cache-culbuteurs-ces codes indiquent quelles sont les options du moteur qui ont ete montees sur ce moteur en usine-pour obtenir les pieces de rechange, donner ces numeros de code accessoire au concessionnaire ou au distributeur du moteur- les deux premiers caracteres de chaque code identifient un groupe particulier, tel que l’alternateur-les deux derniers caracteres de chaque code identifient une option particuliere montee sur ce moteur , par exemple un alternateur de 12 volts et 55 amperes si un moteur est commande sans un composant particulier, les deux derniers caracteres du code accessoire de ce groupe fonctionnel sont des 9 11-2 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=14 1a16 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) option codes description description des codes options zubehoerkode beschreibung cd37241 -un-17feb95 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 11-3 pn=15 1a17 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) option codes description description des codes options zubehoerkode beschreibung cd37242 -un-17feb95 11-4 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=16 1a18 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) generalites concernant les numeros de serie ces informations permettent de determiner les pieces a monter selon le numero de serie de la machine: - la piece peut etre montee sur toutes les machines -000000 la piece peut etre montee sur les machines jusqu’au numero de serie indique inclus 000000- la piece peut etre montee sur les machines a partir du numero de serie indique 000000-000000 la piece peut etre montee sur les machines dont le numero de serie est compris entre les numeros indiques inclus lorsqu’ un numero de serie est remplace par xxxxxx, un changement a ete apporte dans les numeros de serie, mais le numero de serie exact n’etait pas connu au moment de la publication du catalogue- illustrations figurant dans des encadres les pieces figurant dans un encadre sont disponibles en tant que jeu complet; une reference figurant dans la liste des pieces est affectee a ce jeu- un encadre sans reference comprend des pieces d’un ancien assemblage- indication des revisions (catalogues sur microfiches uniquement) les revisions affectant les commandes de pieces sont reperees par des traits verticaux dans la marge gauche des listes de pieces correspondant aux vues eclatees- un trait vertical apparait egalement dans l’ index numerique a gauche du numero de la piece pour localiser l’ information modifiee- genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 11-5 pn=17 1a19 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) index des sections informations moteur - 09 mode d’emploi 11 moteur (cd3029df) - 20 moteur (cd4039df/cd4039tf) - 21 moteur (cd4045tf) - 22 moteur (cd6059tf/cd6068tf) - 23 admission/echappement - 25 systeme d’alimentation - 30 systeme d’injection - 35 demarreur - 40 alternateur - 50 filtre a air - 60 courroie/ventilateur/radiateur - 70 accessoires - 80 tableau de bord - 90 index numerique - 95 11-6 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=18 1a20 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) motorinformation die motoren in diesem katalog werden nur in saran hergestellt-es sind dieselmotoren- in zwei ausfuehrungen selbstsaugend oder mit turbolader- um ihrem john deere ersatzteildepot die arbeit zu erleichtern, sind dem seriennumerschield informationnen ueber den motor typ zu entnehmen- motorseriennummerschild cd37200 -un-01jan94 1- motorhersteller cd - saran 2- anzahl der zylinder 3 oder 4 oder 6 3- gesamter hubraum (in liter) 029 (2-9 l)(bohrung 106-5mm x hub 110mm) 039 (3-9 l)(bohrung 106-5mm x hub 110mm) 045 (4-5 l)(bohrung 106-5mm x hub 127mm) 059 (5-9 l)(bohrung 106-5mm x hub 110mm) 068 (6-8 l)(bohrung 106-5mm x hub 127mm) 4- saugart d - selbstsaugend diesel t - mit turbolader ohne luftkuehlung diesel 5- motorseriennumer 123456 (sechs zahlen) 6- verwendung f (oem) 7- motorversion 123 (drei zahlen, nicht verwendet) genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 12-1 pn=19 1a21 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) aufkleber mit motorzubehoer-schluesselnummern cd37240 -un-17feb95 schluesselnummern fuer motorzubehoer oem motoren werden zusaetzlich zum seriennummerschild mit einemaufkleber mit motorzubehoer- schluesselnummern versehen-der aufkleber ist auf dem ventildeckel angebracht- der zubehoershluessel gibt an, mit welchem zubehoer ihr motor im werk ausgesttatet wurde- teilen sie ihrem autorisierten haendler oder dem motor vetreter diese schluesselnummern mit wenn sie ersatzteile benoetigen oder der motor gewartet werden muss- die ersten beiden stellen jeder schluesselnummer kennzeichnen ein spezifische gruppe,z-b- eine lichtmachine-die letzten beiden stellen jeder schluesselnummer kennzeichnen ein spezielles zubehoerteil mit dem ihr motor ausgestatte wurde,z-b- eine 12 volt 55 ampere lichtmaschine- wenn ein motor ohne spezielles zubehoerteil bestellt wurde sind die letzten beiden stellen dieser gruppen-schluesselnummer zweimal die 9- 12-2 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=20 1a22 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) option codes description description des codes options zubehoerkode beschreibung cd37241 -un-17feb95 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 12-3 pn=21 1a23 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) option codes description description des codes options zubehoerkode beschreibung cd37242 -un-17feb95 12-4 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=22 1a24 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) informationen zur seriennummer seriennummern sind angegeben, um genau feststellen zu koennen, welche teile fuer eine bestimmte maschine verwendet werden- beispiel: - dieses teil kann fuer alle maschinen verwendet werden- -000000 dieses teil kann fuer alle maschinen bis zu der genannten seriennummer verwendet werden- 000000- dieses teil kann fuer alle maschinen ab der genannten seriennummer verwendet werden 000000-000000 dieses teil kann fuer alle maschinen verwendet werden, deren seriennummer zwischen den genannten zahlen liegt- wo anstelle einer seriennummer die angabe xxxxxx steht, erfolgte eine aenderung der betreffenden seriennummer- bei zusammenstellung des ersatzteilkataloges war die genaue seriennummer jedoch noch nicht bekannt- umrandete teile mit einer umrandung versehene teile sind als reparatursatz erhaeltlich und in der ersatzteilliste mit einer entsprechenden nummer gekennzeichnet- umrandete teile ohne teilenummern sind alte teile- kennzeichnung von aenderungen (nur bei microfiche-katalogen) aenderungen bzw- neue angaben, die die bestellung von teilen betreffen, werden durch senkrechte striche am linken seitenrand gekennzeichnet- in nummernindex sind die entsprechenden aenderungen ebenfalls am linken rand mit strichen gekennzeichnet- genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 12-5 pn=23 1a25 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) gruppenindex motorinformation - 09 bedienungsanleitung - 12 motor (cd3029df) - 20 motor (cd4039df/cd4039tf) - 21 motor (cd4045tf) - 22 motor (cd6059tf/cd6068tf) - 23 einlass/auslass - 25 kraftstoffsystem - 30 einspritzanlage - 35 anlasser - 40 drehstromgenerator - 50 luftfilter - 60 riemen/luefter/kuehler - 70 zubehoerteile 80 armaturenbrett - 90 teilenummern-verzeichnis - 95 12-6 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=24 1b1 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) informazioni sul raggruppamento dei motori i motori contenuti in questo catalogo sono costruiti solo a saran- sono disponibili, motori diesel aspirati e motori diesel turbocompressi per aiutare il magazzino john deere a fornirvi un servizio pronto ed efficiente, identificare il tipo di motore tramite la targhetta del numero di serie- targhetta numero di serie del motore cd37200 -un-01jan94 1- indica il costruttore del motore cd - saran 2- indica il numero di cilindri 3 oppure 4 oppure 5 oppure 3- indica la cilindrata totale 029 (2-9 litri)(alesaggio 106-5mm x corsa 110mm) 039 (3-9 litri)(alesaggio 106-5mm x corsa 110mm) 045 (4-5 litri)(alesaggio 106-5mm x corsa 127mm) 059 (5-9 litri)(alesaggio 106-5mm x corsa 110mm) 068 (6-8 litri)(alesaggio 106-5mm x corsa 127mm) 4- indica il tipo di aspirazione d - diesel ad aspirazione naturale t - diesel ad turbocompressi 5- indica il numerodi serie del motore123456 (sei cif re) 6- indica l’utente del motore f (oem) 7- indica la versione 123 (tre cifre,no utilizare) genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 13-1 pn=25 1b2 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) etichetta dei codici opzioni motore cd37240 -un-17feb95 codici acces***i del motore oltre alla targhetta del numero di serie del motore, i motori oem hanno un’etichetta dei codici degli acces***i del motore situata sul coperchio valvole- questi codici indicano quali opzioni del motore sono state montate in officina su questo motore- per ottenere le parti di recambio, fornire questi numeri del codice acces***io al concessionario o al distributore del motrore- i primi due caratteri di ogni codice identificanoun gruppo particolare, come l’alternatore i due ultimi caratteri di ogni codice identificano un’opzione particolare montata su questo motore per esempio : un alternatore da 12 volt e 55 ampere- se un motore e ordinato senza un componente particolare, i due ultimi caratteri del codice acces***io di questo gruppo funzionale sono dei 9 13-2 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=26 1b3 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) descripzione dei codici opzioni descripcion del codigos de las opciones utrustningkodbeskriving cd37243 -un-17aug95 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 13-3 pn=27 1b4 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) descripzione dei codici opzioni descripcion del codigos de las opciones utrustningkodbeskriving cd37244 -un-17aug95 13-4 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=28 1b5 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) informazioni sugli elenchi dei numeri di matricola sono indicate qui di seguito le informazioni relative ai numeri di matricola per spiegare su quale macchina possono essere usate le varie parti- ad esempio: - la parte puo’essere usata su tutte le macchine- -000000 la parte puo’essere usata su tutte le macchine fino al numero di matricola indicato compreso- 000000- la parte puo’essere usata su tutte le macchine a partire dal numero di matricola indicato- 000000-000000 la parte puo’essere usata con numeri di matricola compresi tra quelli indicati- quando in luogo del numero di matricola figurano le xxxxxx, significa che e’stata apportata una variazione al numero di matricola ma il numero di matricola esatto non era disponibile al momento della produzione del catalogo- illustrazione riquadrata un numero di riferimento, indicato nell’elenco parti, e’assegnato ad riquadro che comprende tutte le parti vendute come gruppo di servizio- i pezzi accerchiati senza numero d’identificazione sono pezzi vecchi- linea di segnalazione modifica (solo cataloghi su microfiche) le modifiche che interessano l’ordinazione delle parti sono identificate da linee verticali poste nel margine sinistro delle immagini che elencano le parti revisionate- una riga compare anche sul margine sinistro dello stesso numero di parte nell’indice numerico per mostrare la posizione delle informazioni revisionate- genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 13-5 pn=29 1b6 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) indice della sezione informazioni motori - 09 istruzioni per l’uso - 13 motore (cd3029df) - 20 motore (cd4039df/cd4039tf) - 21 motore (cd4045tf) - 22 motore (cd6059tf/cd6068tf) - 23 aspirazione aria e scarico - 25 sistema combustibile - 30 sistema iniezione - 35 motorino d’avviamento - 40 alternatore - 50 filtro aria - 60 cinghia/ventilatore/radiatore - 70 acces***i - 80 cruscotto - 90 indice numerico - 95 13-6 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=30 1b7 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) informaciones relativas a los motores los motores que aparecen en este catalogo son fabricados unicamente en saran- se trata de motores diesel, con o sin turbocompres*** el numero de serie que aparece en la plaqueta de identificacion permite identificar correctamente el tipo de motor- el deposito de piezas de recambio puede de esta manera suministrar un servicio rapido y eficaz- placa de identificacion del motor cd37200 -un-01jan94 1- planta de fabricacion cd - saran 2- numero de cilindros 3 o 4 o 6 3- cilindrada total en litros 029 (2-9 l)(diametro 106-5mm x carrera 110mm) 039 (3-9 l)(diametro 106-5mm x carrera 110mm) 045 (4-5 l)(diametro 106-5mm x carrera 127mm) 059 (5-9 l)(diametro 106-5mm x carrera 110mm) 068 (6-8 l)(diametro 106-5mm x carrera 127mm) 4- modo de alimentacion d - motor diesel sin turbo compre*** t - motor diesel con turbocompre*** 5- numero de serie del motor 123456 (6 cifras) 6- usuario f (oem) 7- tipo de motor 123 (3 cifras, no utilisadas) genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 14-1 pn=31 1b8 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) etiqueta de codigos de acce***ios del motor cd37240 -un-17feb95 codigos de los acce***ios del motor ademas de la placa del numero de serie del motor, los motores oem tienen una etiqueta de codigos de acce***ios del motor situada sobre la tapa de los balancines- estos codigos indican cuales son las opciones del motor que han sido montadas en este motor en la fabrica- para obtener las piezas de recambio, indicar estos numeros de codigo de acce***ios al concesionario o al distribuidor del motor- los dos primeros caracteres de cada codigo identifican un grupo particular, como el alternador- los dos ultimos caracteres de cada codigo identifican una accion particular montada en este motor- por ejemplo, un alternador de 12 voltios y 55 amperios- si se pide un motor sin un componente particular, los 2 ultimos caracteres del codigo el acce***io de este grupo funcional son 9- 14-2 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=32 1b9 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) descripzione dei codici opzioni descripcion del codigos de las opciones utrustningkodbeskriving cd37243 -un-17aug95 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 14-3 pn=33 1b10 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) descripzione dei codici opzioni descripcion del codigos de las opciones

powertech? 2.9 l diesel engines ctm125 14jun01 (english) component technical manual introduction cd03523,00000db –19–03jan01–1/1 foreword this manual is written for an experienced technician. essential tools required in performing certain service work are identified in this manual&are recommended for use. live with safety: read the safety messages in the introduction of this manual&the cautions presented throughout the text of the manual. this is the safety-alert symbol. when you see this symbol on the machine/in this manual, be alert to the potential for personal injury. use this component technical manual in conjunction with the machine technical manual. an application listing in the introduction identifies product-model/component type-model relationship. see the machine technical manual for information on component removal&installation,&gaining access to the components. this manual is divided in three parts: repair, operation and tests, tools&specifications. repair sections contain necessary instructions to repair the component. operation&tests sections help you identify the majority of routine failures quickly. tools and specifications sections are summary listings of all applicable essential tools, service equipment&tools, other materials needed to do the job, service parts kits, specifications, wear tolerances,&torque values information is organized in groups for the various components requiring service instruction. component technical manuals are concise service guides for specific components. component technical manuals are written as stand-alone manuals covering multiple machine applications. fundamental service information is available from other sources covering basic theory of operation, fundamentals of troubleshooting, general maintenance, and basic type of failures&their causes. read each block of material completely before performing service to check for differences in procedures/specifications. follow only the procedures that apply to the engine model number you are working on. if only one procedure is given, that procedure applies to all the engines in the manual. california proposition 65 warning diesel engine exhaust&some of its constituents are known to the state of california to cause cancer, birth defects&other reproductive harm. ctm125 (14jun01) powertech 2.9 l diesel engines 061401 pn=2 introduction cd03523,00000dc –19–03jan01–1/2 john deere dealers the changes listed below make your ctm obsolete. discard ctm 125 dated 26jun98&replace with this new manual. also, copy these pages&route through your service department. introduction ? updated engine application charts. group 01 ? updated engine model designation. ? updated engine oil&coolant application guidelines. group 02 ? updated engine lifting&cleaning procedures. group 03 ? updated sealant application guidelines. ? updated engine break-in procedure. group 05 ? revised procedure for installation of rocker arm shaft. group 10 ? added general information on connecting rods to include new precision joint? connecting rod. ? revised procedures for removal, inspection and installation of connecting rods, bearings&caps. ? updated information for cap&plug installation in cylinder block. group 15 ? added procedure to remove crankshaft pulley with bolt-in weights. group 20 ? added procedure to remove crankshaft front oil seal. ? added procedure to remove timing gear cover. group 25 ? revised torque specification for oil drain plug. group 30 ? updated information to install coolant heater. ? added exploded view showing radiator installed by john deere. group 35 ? updated turbocharger boost pressure specifications. ? added exploded view showing air filters installed by john deere. group 40 ? updated injection pump specifications including dynamic timing&power rate. ? added procedure to replace throttle lever on stanadyne pump. ? added procedure to adjust aneroid on stanadyne pump. ? added procedure to remove&install delphi/lucas fuel injection pump. ? added information on rate shaping nozzle (rsn). group 110 ? added procedure to test cooling system&radiator cap. group 120 ? added information for delphi/lucas fuel injection pump operation. ? added procedure to test shut-off solenoid on delphi/lucas pump. ? added information on cold start advance operation and test. precision joint is a trademark of deere & company ctm125 (14jun01) powertech 2.9 l diesel engines 061401 pn=3 introduction cd03523,00000dc –19–03jan01–2/2 ? added information on light load advance operation and test. ? added information on rate shaping nozzle (rsn). group 200 ? all essential tools listed throughout this manual are consolidated in this group for ease of reference. group 205 ? all service equipment&recommended tools listed throughout this manual are consolidated in this group for ease of reference. group 210 ? all dealer fabricated tools listed throughout this manual are consolidated in this group for ease of reference. group 300 ? all repair specifications listed throughout this manual are consolidated in this group for ease of reference. group 305 ? all test&diagnostic specifications listed throughout this manual are consolidated in this group for ease of reference. ctm125 (14jun01) powertech 2.9 l diesel engines 061401 pn=4 introduction dpsg,ouoe003,33 –19–28dec98–1/1 powertech? 2.9 l engines cd30517a –un–23feb01 3/4 right rear view cd30518a –un–22feb01 3/4 left rear view cd30519a –un–23feb01 3/4 right front view cd30520a –un–23feb01 3/4 left front view powertech is a registered trademark of deere & company. ctm125 (14jun01) powertech 2.9 l diesel engines 061401 pn=5 introduction cd,ctm125,002 –19–03jan01–1/2 engine application chart this component technical manual (ctm125) covers repair of powertech? 2.9 l engines produced by john deere saran “cd” (france)&by john deere torreon “pe” (mexico). refer to the chart below to know which applications is covered by this manual. note: information on how to remove&reinstall the engine in the vehicle is contained in the relevant technical manual. 5000-series tractors (agritalia-built) engine model observations 5300/5300n cd3029dat01 non-certified 5400/5400n cd3029tat02 non-certified 5010-series tractors (agritalia-built) engine model observations 5310/5310n cd3029dat50 certified 5410/5410n cd3029tat50 certified 5010-series tractors (augusta-built) engine model observations 5105 . pe3029dlv51 certified 5205 . pe3029dlv52 certified 5210 . cd3029dlv50 certified 5210 . pe3029dlv50 certified 5210 . pe3029dlv53 certified 5210 . pe3029dlv54 certified 5310/5310n cd3029tlv50 certified 5310/5310n pe3029tlv50 certified 5310/5310n pe3029tlv52 certified 5020-series tractors (augusta-built) engine model observations 5220 pe3029dlv53 certified 5320/5320n pe3029tlv52 certified engines for goldoni tractors engine model observations cd3029dfg21 . non-certified cd3029dfg22 . non-certified cd3029tfg21 non-certified cd3029dfg51 . certified cd3029tfg51 certified powertech is a registered trademark of deere & company ctm125 (14jun01) powertech 2.9 l diesel engines 061401 pn=6 introduction cd,ctm125,002 –19–03jan01–2/2 oem engines (non-certified) engine model observations engine model observations cd3029df120 cd3029tf120 cd3029df121 cd3029tf121 cd3029df122 cd3029tf123 cd3029df123 cd3029tf160 auxiliary drive cd3029df124 cd3029tf161 auxiliary drive cd3029df128 power unit cd3029tf162 auxiliary drive cd3029df160 auxiliary drive cd3029tf163 auxiliary drive cd3029df161 auxiliary drive pe3029tf120 cd3029df162 auxiliary drive pe3029tf160 auxiliary drive cd3029df163 auxiliary drive cd3029df164 auxiliary drive cd3029df165 auxiliary drive pe3029df120 pe3029df160 auxiliary drive oem engines (certified) engine model observations engine model observations cd3029df150 cd3029tf150 cd3029df151 cd3029tf151 cd3029df152 cd3029tf152 cd3029df180 cd3029tf180 auxiliary drive pe3029df150 pe3029tf150 pe3029df180 auxiliary drive pe3029tf180 auxiliary drive ctm125 (14jun01) powertech 2.9 l diesel engines 061401 pn=7 introduction cd03523,00000dd –19–04jan01–1/1 information relative to emissions regulations depending on the final destination, engines can meet the emissions regulations according to the us environmental protection agency (epa), california air resources board (carb)&for europe, the directive 97/68/ec relating the measures against the emissions of particles&gaseous pollutant from internal combustion engines. such engines are called “certified”&receive an emission label stuck on the engine. the regulations prohibit tampering with the emission-related components listed below which would render that component inoperative/to make any adjustment on the engine beyond published specifications. it is also illegal to install a part or component where the principal effect of that component is to bypass, defeat,/render inoperative any engine component/device which would affect the engine’s conformance to the emission regulations. to summarize, it is illegal to do anything except return the engine to its original published specifications. list of emission-related components: ? fuel injection system ? intake manifold ? turbocharger ? charge air cooling system ? piston ctm125 (14jun01) powertech 2.9 l diesel engines 061401 pn=8 contents group 00—safety group 01—general information group 02—engine mounting group 03—engine rebuilt guide group 05—cylinder head&valves indx group 10—cylinder block, liners, pistons&rods group 15—crankshaft, main bearings&flywheel group 20—camshaft&timing gear train group 25—lubrication system group 30—cooling system group 35—air intake&exhaust system group 40—fuel system group 100—engine tune-up group 105—engine system - operation group 110—engine system - diagnosis&tests group 115—air intake system - operation and tests group 120—fuel system - operation&tests group 200—essential tools group 205—service equipment & recommended tools group 210—self-manufactured tools group 300—repair specifications group 305—diagnostic&test specifications all information, illustrations&specifications in this manual are based on the latest information available at the time of publication. the right is reserved to make changes at any time without notice. copyright ? 2001 deere & company moline, illinois all rights reserved a john deere illustruction? manual previous editions copyright ? 1998 ctm125 (14jun01) i powertech 2.9 l diesel engines 061401 pn=1 contents indx ctm125 (14jun01) ii powertech 2.9 l diesel engines 061401 pn=2 contents page page group 00—safety 00-1 knurl valve guides 05-8 clean&inspect valve seats 05-9 group 01—general information lapping valve seats 05-9 engine identification 01-1 check valve recess 05-10 oem engine option code label 01-2 remove valve seat inserts 05-10 emission certified engine label 01-2 valve seat insert installation 05-12 engine references 01-3 check valves 05-13 basic engine specifications 01-4 grind valves 05-13 longitudinal cut-away 01-5 check valve spring compression 05-14 transversal cut-away 01-6 inspect valve rotators 05-14 general engine description 01-7 install valves 05-14 diesel fuel . 01-8 install cylinder head 05-16 handling&storing diesel fuel 01-8 torque turn tightening method 05-17 diesel engine oil 01-9 disassembling&checking rocker arm lubricant storage 01-10 shaft 05-18 mixing of lubricants 01-10 reassembling rocker arm shaft 05-19 diesel engine coolant 01-11 install rocker arm assembly 05-20 operating in warm temperature climates 01-12 valve clearance 05-20 metric bolt&cap screw torque values 01-13 valve adjustment sequence 05-21 unified inch bolt&cap screw torque install rocker arm cover 05-22 values 01-14 final work . 05-23 group 02—engine mounting group 10—cylinder block, liners, pistons and clean engine 02-1 rods engine lifting procedure 02-1 exploded view 10-1 engine repair stand 02-2 connecting rods - general information 10-2 mounting engine on repair stand 02-3 remove pistons&connecting rods 10-3 measure cylinder liner bore 10-4 group 03—engine rebuilt guide remove cylinder liners 10-4 engine disassembly sequence 03-1 cylinder liner deglazing 10-5 sealant application guidelines 03-2 cylinder block cleaning 10-5 engine re-assembly sequence 03-3 check piston cooling jets 10-6 engine break-in guidelines 03-4 cam follower bore measure 10-6 perform engine break-in 03-4 measure camshaft bore 10-6 diesel engine break-in oil 03-5 remove camshaft bushing 10-7 install camshaft bushing 10-8 group 05—cylinder head&valves measure crankshaft bore 10-8 cylinder head - exploded view 05-1 replace crankshaft bearing caps 10-9 check valve lift 05-2 cylinder block top desk flatness 10-9 remove cylinder head 05-3 measure cylinder liner protrusion 10-10 clean injection nozzle bores 05-5 liner packing installation 10-11 valve actuating parts 05-5 liner o-ring installation 10-11 remove valves&valve springs 05-6 install cylinder liners 10-12 checking cylinder head flatness 05-6 measure connecting rod bearing 10-13 clean valve guides 05-6 measure valve guides 05-7 continued on next page ctm125 (14jun01) 1 powertech 2.9 l diesel engines 061401 pn=1 contents page page rod bearing clearance 10-14 measure camshaft journal 20-4 measure connecting rod bushing 10-14 measure height of cam lobe 20-5 replace connecting rod bushing (3029d) 10-15 replace camshaft gear 20-5 replace connecting rod bushing (3029t) 10-15 tachometer pick-up pin removal 20-5 measure piston pin 10-17 install camshaft 20-6 clean&inspect pistons 10-17 check cam follower 20-7 measure piston pin bore 10-18 idler gear end play measure 20-7 piston top ring groove 10-18 remove front plate 20-8 second&third piston ring grooves 10-18 idler gear bushing&shaft measure 20-9 piston head&skirt checking 10-19 idler gear bushing replacement 20-10 install piston rings 10-20 remove idler shaft 20-10 piston rings staggering 10-20 install idler shaft spring pin 20-11 piston/liner set information 10-21 install idler shafts 20-12 assemble piston&connecting rod 10-22 front plate gasket 20-13 install piston&connecting rod 10-22 install front plate 20-14 measure piston protrusion 10-25 install upper timing gear train 20-15 complete final assembly 10-26 install lower timing gear train 20-16 install oil deflector 20-17 group 15—crankshaft, main bearings&timing gear cover identification 20-17 flywheel install timing gear cover 20-18 remove crankshaft pulley 15-1 install crankshaft front oil seal 20-19 install crankshaft pulley 15-1 install wear ring 20-19 check pulley wobble (engine with front pto) 15-2 install auxiliary equipment 20-20 remove pto pulley 15-2 install pto pulley 15-3 group 25—lubrication system flywheel removal 15-4 oil cooler identification 25-1 flywheel ring gear replacement 15-5 remove oil cooler 25-1 install ball bearing 15-5 replace oil cooler nipple 25-2 install flywheel 15-6 install oil cooler on standard engine 25-2 remove crankshaft rear oil seal 15-6 replace oil cooler/filter bracket on flywheel housing replacement 15-9 engine with auxiliary drive 25-3 install oil seal/wear sleeve 15-9 replace oil filter adapter on engine with crankshaft end play measure 15-11 remote oil filter 25-4 remove crankshaft 15-11 remove oil pressure regulating valve 25-4 crankshaft inspection 15-12 replace oil pressure regulating valve seat 25-5 check crankshaft journal diameter 15-13 install oil pressure regulating valve 25-5 determine crankshaft main bearing replace oil dipstick guide 25-6 clearance using plastigage? 15-14 replace oil by-pass valve 25-6 regrind crankshaft 15-14 replace oil pump strainer 25-7 crankshaft regrinding guidelines 15-15 remove oil pump 25-7 micro-finishing specifications 15-16 oil pump gear axial clearance 25-7 replace crankshaft gear 15-16 oil pump gear radial clearance 25-8 install main bearing inserts 15-17 oil pump specifications 25-8 install 2-piece thrust bearing 15-17 oil pump installation 25-9 install 6-piece thrust bearing 15-18 install oil pan 25-11 crankshaft installation 15-19 group 30—cooling system group 20—camshaft&timing gear train water pump — exploded view 30-1 remove crankshaft front oil seal 20-1 remove water pump 30-1 remove timing gear cover 20-1 disassemble water pump 30-2 measure timing gear backlash 20-2 assemble water pump 30-3 camshaft end play measure 20-3 remove camshaft 20-4 continued on next page ctm125 (14jun01) 2 powertech 2.9 l diesel engines 061401 pn=2 contents page page install water pump 30-5 bleed fuel system 40-32 inspect thermostat 30-6 check engine speed 40-34 cold start advance switch 30-6 cooling system deaeration 30-7 group 100—engine tune-up check fan/alternator belt tension 30-8 preliminary engine testing 100-1 install fan 30-9 general tune-up recommendations 100-1 coolant heater 30-10 radiator exploded view (cd3209df128) 30-12 group 105—engine system - operation lubrication system 105-1 group 35—air intake&exhaust system cooling system 105-4 check air inlet pipe 35-1 exhaust manifold inspection 35-2 group 110—engine system - diagnosis&tests remove turbocharger 35-3 diagnose engine malfunctions 110-1 turbocharger cut-away view (schwitzer) 35-4 checking engine compression 110-4 check radial clearance 35-5 check engine oil pressure 110-5 check axial clearance 35-6 measure engine blow-by 110-5 repair turbocharger 35-6 using stanadyne “time-trac” as prelube turbocharger 35-6 tachometer 110-6 install turbocharger 35-7 inspect thermostat&test opening turbocharger break-in 35-9 temperature 110-7 recommendations for turbocharger use 35-9 pressure test cooling system and air filter exploded view 35-10 radiator cap 110-8 group 40—fuel system replace fuel filter element 40-1 group 115—air intake system - operation and replace fuel filter assembly 40-2 tests replace fuel supply pump 40-3 turbocharger operation 115-1 remove stanadyne db2/db4 fuel check turbocharger boost pressure 115-1 injection pump 40-3 diagnosing turbocharger malfunctions 115-2 repairs to stanadyne fuel injection pump 40-5 replace throttle lever (stanadyne) 40-6 group 120—fuel system - operation&tests aneroid replacement (stanadyne) 40-6 general operation 120-1 aneroid field adjustment (stanadyne) 40-7 fuel supply pump operation 120-2 aneroid workshop adjustment (stanadyne) 40-8 measure fuel supply pump pressure 120-2 install stanadyne db2/db4 fuel fuel filter operation 120-3 injection pump 40-9 stanadyne fuel injection pump (db2/db4) remove delphi/lucas fuel injection pump 40-11 - operation 120-4 repairs to delphi/lucas fuel injection delphi/lucas fuel injection pump pump 40-12 (dp200 shown) - operation 120-6 install delphi/lucas fuel injection pump 40-13 test shut-off solenoid on delphi/lucas dynamic timing 40-15 injection pump 120-8 install timing sen*** 40-16 cold start advance system operation 120-9 install magnetic probe 40-17 check cold start advance system timing sen***&magnetic probe operation 120-12 connection 40-18 check cold start switch operation 120-14 check fuel injection pump timing台湾强鹿6081发动机活塞缸套组件一级代理,曲靖JohnDeere电热塞el502079供应商,陇南JohnDeere加大连杆瓦RE65909多少钱,白城强鹿柴油机缸套R116397批发价,安庆约翰迪尔拖拉机发动机飞轮壳厂家供应,牡丹江约翰迪尔柴油机止推轴承批发,基隆约翰迪尔柴油发电机组飞轮壳厂家供货,宝鸡强鹿JOHNDEERE柴油发动机原厂活塞环厂家供货,铜陵约翰迪尔强鹿气门室盖垫片R123542价格行情,自贡强鹿后油封RE520036哪家买,南京约翰迪尔强鹿后油封RE520036价格,鄂尔多斯强鹿RE507799连杆一级代理,厦门强鹿连杆瓦RE529318价格行情,湛江约翰迪尔6081柴油机加大止推轴承瓦厂家价格,七台河强鹿汽缸垫RE522278批发价,白山约翰迪尔强鹿3029柴油机喷油器价格行情,佛山约翰迪尔加大连杆瓦RE65908B厂家批发,昭通约翰迪尔拖拉机发动机连杆找哪家,漳州约翰迪尔水泵RE546918市场报价,拉萨JohnDeere发动机四配套IK526975供货商,北海约翰迪尔装载机发动机单体泵哪里买,梧州强鹿滤芯滤清器RE62418供货商,保山约翰迪尔6090柴油机缸套密封水圈厂家价格,廊坊供应美国原装6068约翰迪尔机油滤清器RE504836厂家价格,威海约翰迪尔加大止推轴承瓦RE65912批发,青岛JohnDeere活塞销卡簧E1343FN批发价,安阳强鹿燃油泵RE502513代理,无堂划分域约翰迪尔柴油机气门座圈R501640供应商,常德JohnDeere张紧轮RE518097批发商,南宁Johndeere发电机水泵总成代理,襄阳强鹿柴滤RE520842批发价,抚顺johndeere约翰迪尔强鹿柴油机节温器供货商,甘孜强鹿柴油机大修包RE526965一级代理,郑州约翰迪尔强鹿7930拖拉机RE541925油水分离燃油滤清器厂家供货,崇左强鹿柴油机节温器座多少钱,永州约翰迪尔柴油机活塞缸套组件厂家供应,临沧强鹿排气门导管R119132哪家买,伊犁约翰迪尔拖拉机发动机大小瓦市场报价,十堰强鹿柴油发动机柴油泵厂家供货,大连强鹿柴油机3029燃油泵供货商,绵阳JohnDeereTRA64354节恒温器价格行情,海北JohnDeere排气门异管RE518083哪里买,呼和浩特约翰迪尔6068HF158启动机多少钱,桂林约翰迪尔发动机气门帽供应商,锦州美国JohnDeere曲轴前油封RE54073价格,呼和浩特强鹿柴油发动机副线束供货商,茂名强鹿柴油机连杆瓦RE65908价格,云浮强鹿活塞环价格诚信推荐,汉中强鹿柴油机风扇叶厂家供应,赣州美国强鹿Johndeere连杆瓦RE65908多少钱, 40-18 light load advance operation 120-14 fuel injection nozzle identification 40-22 check light load advance operation 120-15 remove fuel injection nozzle 40-23 fuel injection nozzles - general information 120-16 clean fuel injection nozzle 40-24 diagnosing fuel system malfunctions 120-18 fuel injection nozzle test 40-25 testing fuel injection nozzles on a fuel injection nozzle disassembly 40-28 running engine 120-19 adjust fuel injection nozzle 40-29 install fuel injection nozzle 40-30 continued on next page ctm125 (14jun01) 3 powertech 2.9 l diesel engines 061401 pn=3 contents page group 200—essential tools essential tools 200-1 group 205—service equipment & recommended tools service equipment & recommended tools 205-1 group 210—self-manufactured tools template for front plate replacement 210-1 group 300—repair specifications cylinder head&valves specifications 300-1 cylinder block, liners, pistons&rods specifications 300-4 crankshaft, main bearings&flywheel specifications 300-7 camshaft&timing gear train specifications 300-9 lubrication system specifications 300-13 oil dipstick guide height specifications 300-15 cooling system specifications 300-19 distance from pulley/hub to water pump housing sealing surface specifications 300-20 air intake&exhaust system specifications 300-23 fuel system specifications 300-26 group 305—diagnostic&test specifications diagnostic&test specifications 305-1 ctm125 (14jun01) 4 powertech 2.9 l diesel engines 061401 pn=4 group 00 safety 00 1 dx,flame –19–29sep98–1/1 handle fluids safely—avoid fires ts227 –un–23aug88 when you work around fuel, do not smoke/work near heaters/other fire hazards. store flammable fluids away from fire hazards. do not incinerate/puncture pressurized containers. make sure machine is clean of trash, grease,&debris. do not store oily rags; they can ignite&burn spontaneously. dx,sparks –19–03mar93–1/1 prevent battery explosions ts204 –un–23aug88 keep sparks, lighted matches,&open flame away from the top of battery. battery gas can explode. never check battery charge by placing a metal object across the posts. use a volt-meter/hydrometer. do not charge a frozen battery; it may explode. warm battery to 16°c (60°f). dx,fire2 –19–03mar93–1/1 prepare for emergencies ts291 –un–23aug88 be prepared if a fire starts. keep a first aid kit&fire extinguisher handy. keep emergency numbers for doctors, ambulance service, hospital,&fire department near your telephone. ctm125 (14jun01) 00-1 powertech 2.9 l diesel engines 061401 pn=13 safety 00 2 dx,poison –19–21apr93–1/1 prevent acid burns ts203 –un–23aug88 sulfuric acid in battery electrolyte is poisonous. it is strong enough to burn skin, eat holes in clothing,&cause blindness if splashed into eyes. avoid the hazard by: 1. filling batteries in a well-ventilated area. 2. wearing eye protection&rubber gloves. 3. avoiding breathing fumes when electrolyte is added. 4. avoiding spilling/dripping electrolyte. 5. use proper jump start procedure. if you spill acid on yourself: 1. flush your skin with water. 2. apply baking soda/lime to help neutralize the acid. 3. flush your eyes with water for 15—30 minutes. get medical attention immediately. if acid is swallowed: 1. do not induce vomiting. 2. drink large amounts of water/milk, but do not exceed 2 l (2 quarts). 3. get medical attention immediately. ctm125 (14jun01) 00-2 powertech 2.9 l diesel engines 061401 pn=14 safety 00 3 dx,fluid –19–03mar93–1/1 avoid high-pressure fluids x9811 –un–23aug88 escaping fluid under pressure can penetrate the skin causing serious injury. avoid the hazard by relieving pressure before disconnecting hydraulic/other lines. tighten all connections before applying pressure. search for leaks with a piece of cardboard. protect hands and body from high pressure fluids. if an accident occurs, see a doctor immediately. any fluid injected into the skin must be surgically removed within a few hours/gangrene may result. doctors unfamiliar with this type of injury should reference a knowledgeable medical source. such information is available from deere & company medical department in moline, illinois, u.s.a. dx,wear –19–10sep90–1/1 wear protective clothing ts206 –un–23aug88 wear close fitting clothing&safety equipment appropriate to the job. prolonged exposure to loud noise can cause impairment or loss of hearing. wear a suitable hearing protective device such as earmuffs/earplugs to protect against objectionable or uncomfortable loud noises. operating equipment safely requires the full attention of the operator. do not wear radio/music headphones while operating machine. ctm125 (14jun01) 00-3 powertech 2.9 l diesel engines 061401 pn=15 safety 00 4 dx,loose –19–04jun90–1/1 service machines safely ts228 –un–23aug88 tie long hair behind your head. do not wear a necktie, scarf, loose clothing,/necklace when you work near machine tools/moving parts. if these items were to get caught, severe injury could result. remove rings&other jewelry to prevent electrical shorts&entanglement in moving parts. dx,air –19–17feb99–1/1 work in ventilated area ts220 –un–23aug88 engine exhaust fumes can cause sickness/death. if it is necessary to run an engine in an enclosed area, remove the exhaust fumes from the area with an exhaust pipe extension. if you do not have an exhaust pipe extension, open the doors&get outside air into the area dx,clean –19–04jun90–1/1 work in clean area t6642ej –un–18oct88 before starting a job: ? clean work area&machine. ? make sure you have all necessary tools to do your job. ? have the right parts on hand. ? read all instructions thoroughly; do not attempt shortcuts. ctm125 (14jun01) 00-4 powertech 2.9 l diesel engines 061401 pn=16 safety 00 5 dx,paint –19–03mar93–1/1 remove paint before welding/heating ts220 –un–23aug88 avoid potentially toxic fumes&dust. hazardous fumes can be generated when paint is heated by welding, soldering,/using a torch. do all work outside/in a well ventilated area. dispose of paint&solvent properly. remove paint before welding/heating: ? if you sand/grind paint, avoid breathing the dust. wear an approved respirator. ? if you use solvent/paint stripper, remove stripper with soap&water before welding. remove solvent or paint stripper containers&other flammable material from area. allow fumes to disperse at least 15 minutes before welding/heating. dx,torch –19–03mar93–1/1 avoid heating near pressurized fluid lines ts953 –un–15may90 flammable spray can be generated by heating near pressurized fluid lines, resulting in severe burns to yourself&bystanders. do not heat by welding, soldering,/using a torch near pressurized fluid lines or other flammable materials. pressurized lines can be accidentally cut when heat goes beyond the immediate flame area. dx,light –19–04jun90–1/1 illuminate work area safely ts223 –un–23aug88 illuminate your work area adequately but safely. use a portable safety light for working inside/under the machine. make sure the bulb is enclosed by a wire cage. the hot filament of an accidentally broken bulb can ignite spilled fuel/oil. ctm125 (14jun01) 00-5 powertech 2.9 l diesel engines 061401 pn=17 safety 00 6 dx,lift –19–04jun90–1/1 use proper lifting equipment ts226 –un–23aug88 lifting heavy components incorrectly can cause severe injury/machine damage. follow recommended procedure for removal and installation of components in the manual. dx,serv –19–17feb99–1/1 practice safe maintenance ts218 –un–23aug88 understand service procedure before doing work. keep area clean&dry. never lubricate, service,/adjust machine while it is moving. keep hands, feet ,&clothing from power-driven parts. disengage all power&operate controls to relieve pressure. lower equipment to the ground. stop the engine. remove the key. allow machine to cool. securely support any machine elements that must be raised for service work. keep all parts in good condition&properly installed. fix damage immediately. replace worn/broken parts. remove any buildup of grease, oil,/debris. on self-propelled equipment, disconnect battery ground cable (-) before making adjustments on electrical systems or welding on machine. on towed implements, disconnect wiring harnesses from tractor before servicing electrical system components or welding on machine. ctm125 (14jun01) 00-6 powertech 2.9 l diesel engines 061401 pn=18 safety 00 7 dx,repair –19–17feb99–1/1 use proper tools ts779 –un–08nov89 use tools appropriate to the work. makeshift tools and procedures can create safety hazards. use power tools only to loosen threaded parts and fasteners. for loosening&tightening hardware, use the correct size tools. do not use u.s. measurement tools on metric fasteners. avoid bodily injury caused by slipping wrenches. use only service parts meeting john deere specifications. dx,drain –19–03mar93–1/1 dispose of waste properly ts1133 –un–26nov90 improperly disposing of waste can threaten the environment&ecology. potentially harmful waste used with john deere equipment include such items as oil, fuel, coolant, brake fluid, filters,&batteries. use leakproof containers when draining fluids. do not use food/beverage containers that may mislead someone into drinking from them. do not pour waste onto the ground, down a drain,/into any water source. air conditioning refrigerants escaping into the air can damage the earth’s atmosphere. government regulations may require a certified air conditioning service center to recover&recycle used air conditioning refrigerants. inquire on the proper way to recycle/dispose of waste from your local environmental/recycling center,/from your john deere dealer. ctm125 (14jun01) 00-7 powertech 2.9 l diesel engines 061401 pn=19 safety 00 8 dx,live –19–25sep92–1/1 live with safety ts231 –19–07oct88 before returning machine to customer, make sure machine is functioning properly, especially the safety systems. install all guards&shields. ctm125 (14jun01) 00-8 powertech 2.9 l diesel engines 061401 pn=20 group 01 general information 01 1 cd,ctm125,003 –19–04jan01–1/1 engine identification cd30522 –un–17jun98 cd30521 –un–30apr98 saran engine plate cd30523 –un–17jun98 torreon engine plate engines can be identified from the serial number plate (a) located on the right-hand side of engine. 1. each engine has a 13-digit john deere engine serial number (b) identifying the producing factory, engine model designation,&a 6-digit sequential number. the following is an example: cd3029d500000 cd . producing factory cd= saran-france pe= torreon-mexico 3029 engine model designation 3 = number of cylinders 029 = total displacement (029 = 2.9 liters) d aspiration code d= naturally aspirated t= turbocharger 500000 sequential serial number 2. the second line of information (c) identifies the engine/machine/oem relationship. see “engine application chart” earlier in this manual. 3029df150 3029d see above f . user code at= agritalia-built tractors f = oem applications fg= goldony (italy) kv= john deere knoxville lv== john deere augusta 150 . application number 3. the second line can also contains the ab***ption coefficient (d) of smoke emissions (saran-built engines only). ctm125 (14jun01) 01-1 powertech 2.9 l diesel engines 061401 pn=21 general information 01 2 cd,ctm125,004 –19–01dec97–1/1 oem engine option code label cd30524 –un–27may98 option code label an option code label is secured to the top of the valve cover&identifies the factory installed options on each oem engine to ensure correct parts acquisition. always provide option code information&engine base code when ordering repair parts. a listing of option codes is given in parts catalogs&operator’s manual. note: before “hot tank” cleaning, ensure that option codes are recorded elsewhere. cd,ctm125,228 –19–01dec97–1/1 emission certified engine label cd30697 –un–17jun98 emission label emission certified engines have a label, like the one shown, stuck on the rocker arm cover. information on this label states the conditions this engine is emission certified. ctm125 (14jun01) 01-2 powertech 2.9 l diesel engines 061401 pn=22 general information 01 3 cd,ctm125,005 –19–01dec97–1/1 engine references cd30525 –un–04may98 direction of engine rotation: clockwise rotation when viewed from water pump end. engine front reference: the water pump end is the “front” of the engine. cylinder number 1 is at the front of engine. engine side references: “right-hand”&“left-hand” sides are determined by facing the flywheel end (rear) of the engine. right-hand side is the camshaft side while left-hand side is the fuel injection pump side. ctm125 (14jun01) 01-3 powertech 2.9 l diesel engines 061401 pn=23 general information 01 4 cd,ctm125,040 –19–01dec97–1/1 basic engine specifications unit of 3029d 3029t measure number of cylinders --- 3 3 bore mm 106.5 106.5 (in.) (4.19) (4.19) stroke mm 110 110 (in.) (4.33) (4.33) displacement l 2.9 2.9 (in.3) (179) (179) compression ratio --- 17.8:1 17.8:1 firing order --- 1-2-3 1-2-3 injection system --- direct direct aspiration --- natural turbocharged rated speeda rpm 2500 2500 powerb kw 43 59 @ rated speed (hp) (58) (79) powerb kw 35 @ 1800 rpm (hp) (47) powerb kw 31 @ 1500 rpm (hp) (42) weight (dry) kg 323 330 (lbs) (712) (728) avary by application; refer to the machine technical/operator’s manual for specific engine speeds&powers. bwithout fan. ctm125 (14jun01) 01-4 powertech 2.9 l diesel engines 061401 pn=24 general information 01 5 cd,ctm125,013 –19–01dec97–1/1 longitudinal cut-away cd30529 –un–16jun98 1—fan 6—oil pan 11—flywheel housing 16—cylinder head 2—belt fan 7—oil pump 12—flywheel 17—exhaust valve 3—timing gear 8—oil pump intake 13—cylinder liner 18—rocker arm cover 4—crankshaft pulley 9—connecting rod 14—piston 19—intake valve 5—timing gear cover 10—crankshaft 15—cylinder block 20—water pump ctm125 (14jun01) 01-5 powertech 2.9 l diesel engines 061401 pn=25 general information 01 6 cd,ctm125,014 –19–01dec97–1/1 transversal cut-away cd30530 –un–16jun98 1—air inlet 5—camshaft 9—connecting rod 13—valve 2—cylinder head 6—crankshaft 10—cylinder liner 14—rocker arm 3—push rod 7—cylinder block 11—piston 15—rocker arm cover 4—cam follower 8—oil pan 12—exhaust manifold ctm125 (14jun01) 01-6 powertech 2.9 l diesel engines 061401 pn=26 general information 01 7 cd,ctm125,206 –19–01dec97–1/1 general engine description the powertech? 2.9 l engine is a 3 cylinders, vertical, in-line, valve-in-head, 4-stroke diesel engine. the direct fuel injection is provided by a rotary-type injection pump&9.5 mm injection nozzles mounted in cylinder head. injection pump is driven by the crankshaft through the timing gear train. a cold start advance system allows easy start-up when engine is cold. the “wet” cylinder liners (liner forms cylinder&is surrounded with coolant) can be replaced individually. the pistons are made of high-grade cast aluminum alloy with internal ribbing. the skirt is cam ground to allow for expansion during operation. the piston crown has a cut-out re-entrant bowl swirl chamber to reduce particulate matters&smoke. the three piston rings, 2 for compression&1 for oil control, are located above piston pin. the top compression ring is a keystone shaped ring located close to the top of piston for improved engine performance. the hardened piston pins are fully-floating&held in position by means of snap rings. spray jets (piston cooling orifices) in cylinder block spray pressurized oil on the underside of the piston to lubricate piston pins and cool pistons. the crankshaft is a one-piece, heat treated, nodular-iron. it is supported in replaceable two-piece main bearings machined to close tolerances. the rear thrust bearing has a flange on each side to support crankshaft thrust&to limit end play. the connecting rods have a bronze bushing as bearing surface for the piston pins. the steel-backed rod bearings are aluminum lined&tin plated. some connecting rods have a tapered pin-end while others have a straight pin-end. the camshaft is timed to the crankshaft through the timing gear train. camshaft rotates in a bushing for the no. 1 camshaft journal&directly in honed cylinder block bores for the others camshaft journals. the camshaft lobes determine duration&lift of each valve,&operate the fuel supply pump. the intake&exhaust valves are supported in the cylinder head. the valve stems slide in bores in the cylinder head. the rocker arm shaft assembly is fitted on top of the cylinder head. the engine is supplied with lubricating oil by a gear pump. the lubricating oil passes through a full-flow oil filter in the main oil circuit. to ensure engine lubrication, the oil filter is provided with a by-pass valve which opens when the filter element is restricted. on most engines, engine oil is cooled by means of an oil cooler mounted externally on the cylinder block. engine oil passes through the oil cooler before flowing to the oil filter. a by-pass valve located between oil pump&main gallery relieves any pressure build-up in this area. the engine has a

渭南潼关县帕金斯柴油发电机组配件现货供应中心,荆州监利县FGWilson发电机不能开机维修资料欢迎咨询?,葫芦岛兴城康明斯空滤供应服务商?,怀化新晃请问哪有卖帕金斯发动机零件谁知道多少钱,山南措美县perkins发动机气门室盖原厂专卖,嘉兴秀洲Perkins单体泵批发商,